1. Introduction

This document will try to make a brief summary about Non-Ferrous Metals (NF) processing in SAP SD. I will try not to go into full detail, as in this case this document will rather look like a short book, but explain mandatory activities in order to start using NF processing from scratch. A dedicated consultant will be able to handle the situation afterwards.

NF Processing mainly addresses non-ferrous metals industry sector (copper, aluminum) in which prices can change drastically within minutes or seconds. The prices are determined by London Metal Exchange (LME) globally.

NF Processing in SAP is not limited to NF Metals only. One can use NF processing for any type of goods if the prices do change within short periods of time, or pricing agreements with customer depend on future pricing dates. A typical example will explain this situation: When a salesperson is trying to sell a NF-related product to a customer, he can:

- Come to an agreement price of that very specific time. i.e. LME price at that exact moment can be, say, 1802,64$/TON. They come to an agreement with the customer and fix the price. “Fixing the price” means that this would be the selling price of NF metal’s LME for that sales order, and any price change will not affect its price. (Prices vary within very short periods of time)

- Come to an agreement price of a future day’s price. That future day can be days or even months away. i.e: The price is fixed on the LME closing price on the day of Goods Issue. So in the sales order today’s price will be seen, but in the billing document, LME price should be recalculated according to Goods Issue. The price should only be recalculated for LME; other condition types need not be recalculated. This price can be higher or fewer than current price, so it’s almost a gambling on both sides (Pricing agreements with customer depend on future pricing dates)

If any of the above is common in your business scenario, you should take a look at NF Processing to see if it helps you meet your complex requirements.

2. NF Metals Activation

First of all, business function set DIMP for Mill Products need to be activated via Switch Framework Customizing (SFW5).

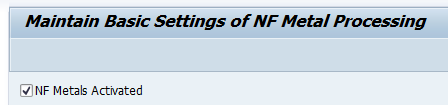

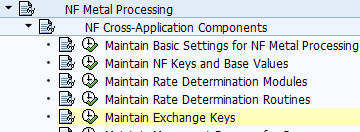

In order to use NF Processing, a content activation is required. This is done in SPRO via path Logistics – General -> NF Metal Processing -> NF Cross-Application Components -> Maintain Basic Settings For NF Metal Processing. You just need to tick the field here.

3. Exchange Keys

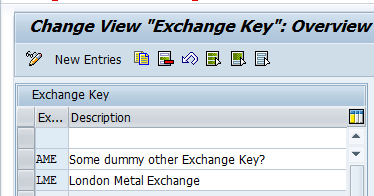

In order to distinguish customers who you work via LME and who you don’t, you need to maintain exchange keys. This is done via customizing Maintain Exchange Keys.

Here you can create different Exchange Keys. For example, if your client is selling both NF metals and gold, you should probably create two different keys: One for LME, and one for Gold Exchange.

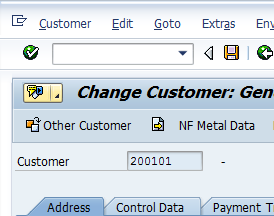

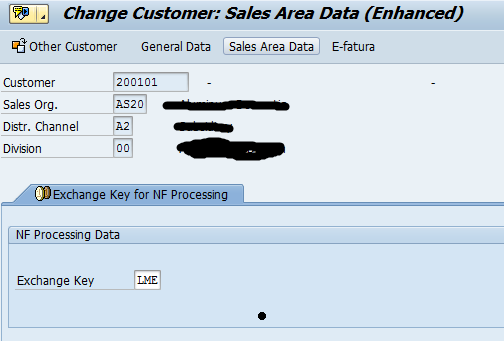

This exchange key must be assigned to customer in customer master data. In customer master, a new button should appear with title as NF Metal Data.

Assignment of Exchange key to customer master is done here at sales area level. Technically the entry here is stored in KNVV-J_1NBOESL.

4. NF Keys and Base Values

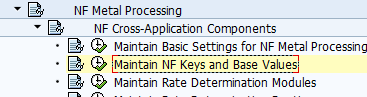

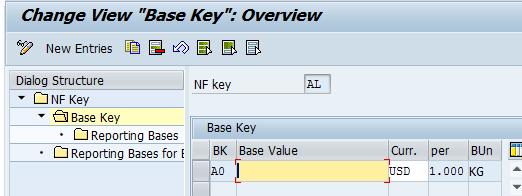

In order to distinguish NF metals from others, you need to maintain NF keys. For materials, this is done via customizing Maintain NF Keys and Base Values.

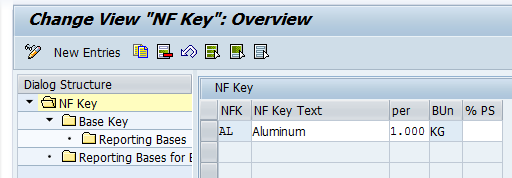

Here you can define NF Keys and base quantity and unit of measure for pricing. For example, in Aluminum sector, LME prices are maintained per TON, so the value you see below represents this (1TON = 1000KG).

In this cluster view, when you select Base Key, you can define a base price per unit which is to be added to LME price. If this is not required for your industry sector, this will be obsolete. In the screen below, you can see that for base key A0, price is 0.

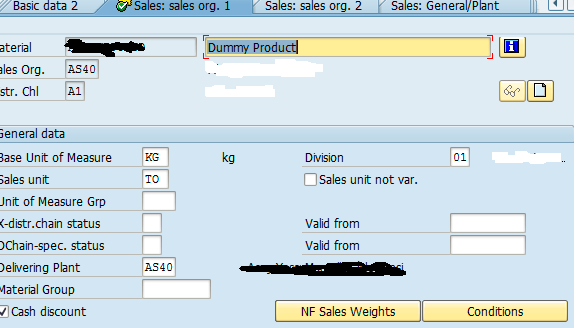

Assignment of NF key to Base Key to material master is done at distribution chain level, Sales: Sales Org. Data 1 view. As you can see below, there is a separate button for maintaning this information, named as NF Sales Weights.

More than one base key can be assigned to a NFkey, and more than one NF key can be assigned to a material in a distribution chain. This means you can use Base keys to differentiate selling prices for materials which use the same NF key.

Use case example: You create two base keys for the same NF key. For base key A0 you leave the price blank. For base key A1 you set the price as 250$/TON. For raw materials, you assign base key A0; and for finished products, you assign base key A1. This way in sales documents, while your raw materials will be charged with LME price, your finished goods will be charged with LME price + 250$/TON).

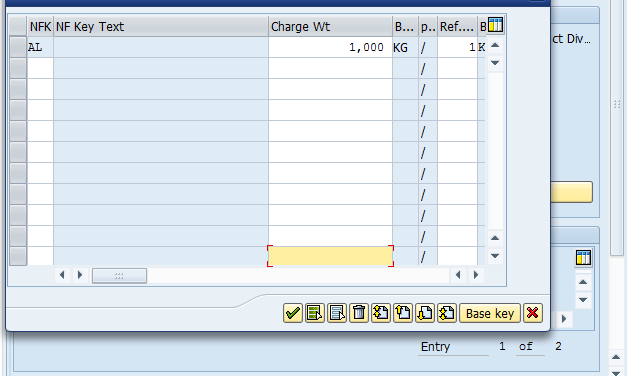

In material master, when you click NF Sales Weights button, a popup screen will appear like below:

Here NF key is appended as a row. You can assign the Base key which has been assigned to NF keys beforehand from the Base key button (i.e. A0 or A1).

5. LME Condition Type

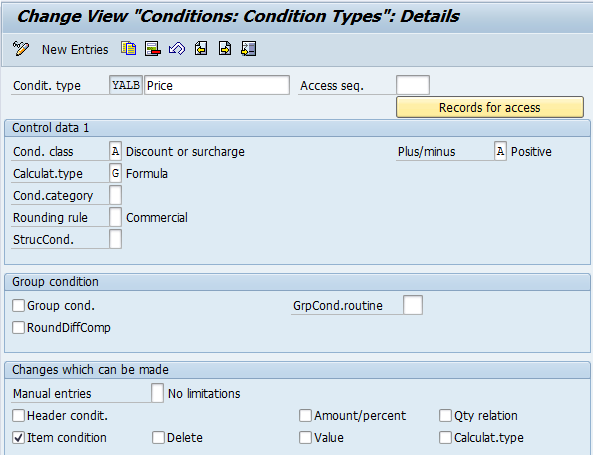

In NF processing, LME prices are mapped to condition types. First you should create your own condition type via V/06, and this condition type should not have an access sequence in it. If your customer is a manufacturer in NF Processing, this condition type would probably be a surcharge, not a price, as additional prices might be added to LME price as well (i.e. Labour Price).

For your reference, the condition type I’ve created has the following attributes:

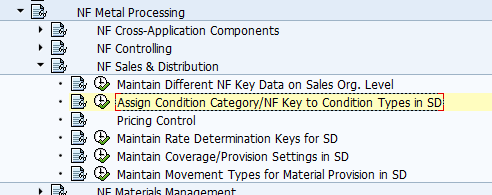

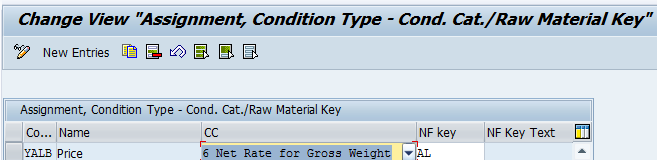

Telling SAP that this is NF Price, not a usual condition type, is done via customizing Assign Condition Category/NF Key to Condition Types in SD.

Here you assign your condition type to a NF key and a condition category.

In your pricing procedure your LME condition type should be mandatory. You need to assign a requirement formula and a condition base formula for your LME condition type. In standard SAP, requirement formula 461 (LV61A461) and condition base formula 461 (FV63A461) are created for this purpose. Requirement formula 461 checks if your material is a NF metal (Assignment of NF key in the relevant distribution chain). Condition base formula 461 reads LME pricing information from relevant tables.

6. LME Master Data

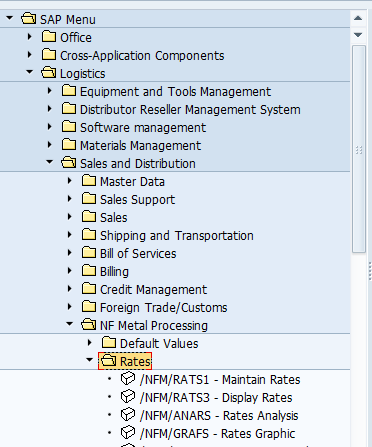

LME prices should be created as master data. This can be handled either manually by users or automatically via a web service from London Metal Exchange. SAP Menu path for manual maintenance (/NFM/RATS1) and price analysis (/NFM/ANARS) are as below:

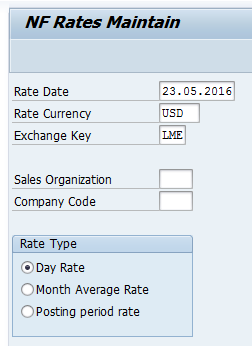

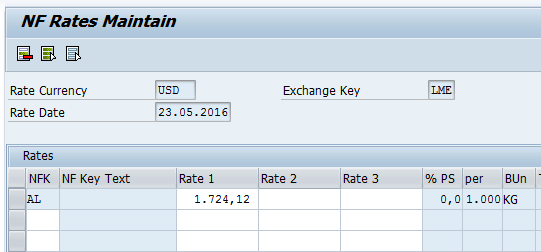

In manual maintenance, you enter Rate Date, Rate Currency, Exchange Key and Rate Type.

Sales organization and/or Company Code entrance is optional, as LME prices are not dependant on organizational data, but you have the option to differentiate prices on them if required.

You enter the NF key and the rate and save your entries. Rate 1, Rate 2 and Rate 3 can be used to differentiate prices for the same date (i.e. you usually use Day Closing price for Rate 1, but Day Opening price for Rate 2, vs…)

7. NF Routines

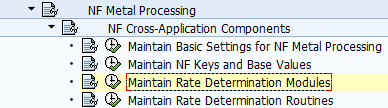

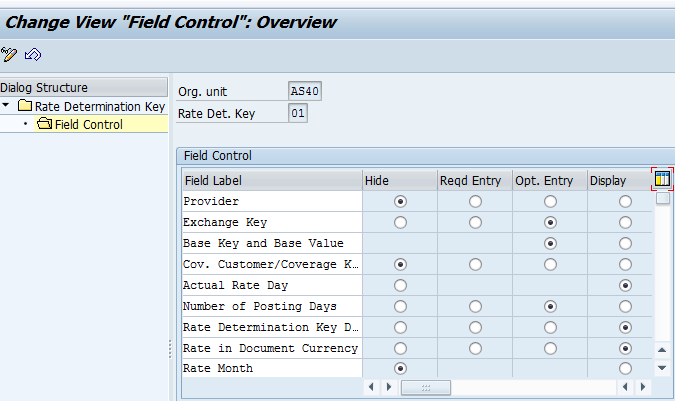

In NF metals pricing there is a VOFM-like functionality where you maintain routines by coding and assign them in your processes. SPRO path for this is as follows:

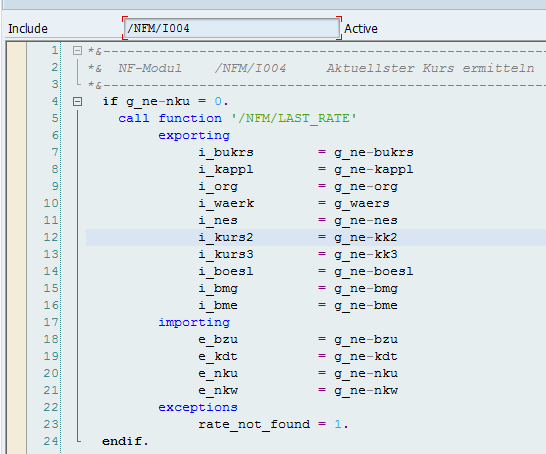

This is a three step process. First, you create rate determination modules (which look like VOFM routines). A typical example is include /NFM/I004 “Determine most recent rate”:

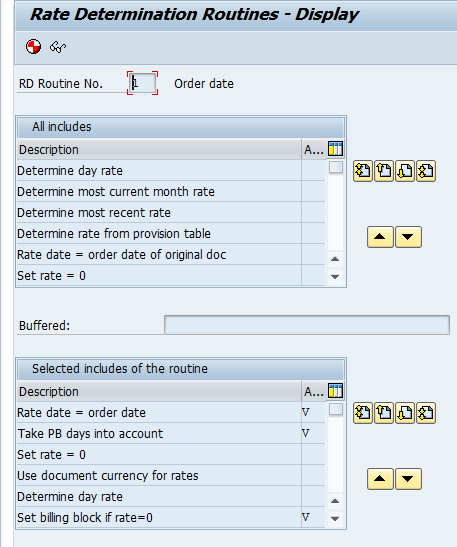

In the second step, you assign your modules to rate determination modules. This is where it differs from VOFM routines, as more than one rate determination module can be assigned to a rate determination routine. All modules are listed on the upper side, and selected modules for your routine are listed on the down side. All the modules in the routine will be read in sequence by pricing if your routine is assigned to Sales organization / Rate determination key (see 8. Rate Determination Key).

Third step will be a customizing assignment, which is:

8. Rate Determination Key

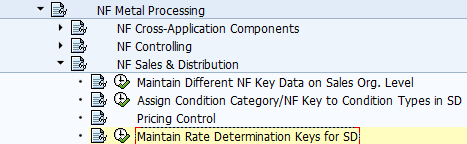

In customizing activity Maintain Rate Determination Keys for SD, you decide on which Sales organization which rate determination keys can be used.

Rate determination keys (RDK) are used to differentiate pricing logic for the application.

In this customizing;

Org.: Sales organization

RDK: Rate determination key (created here on the fly for each sales organization separately)

RDR: Rate determination module

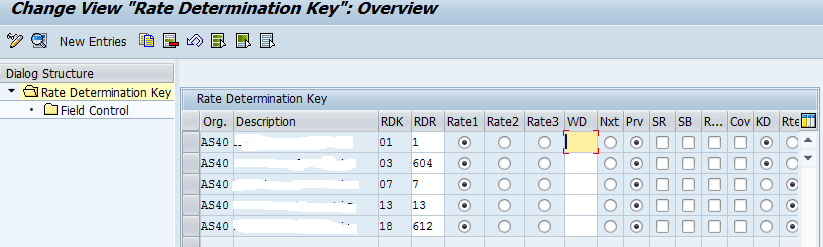

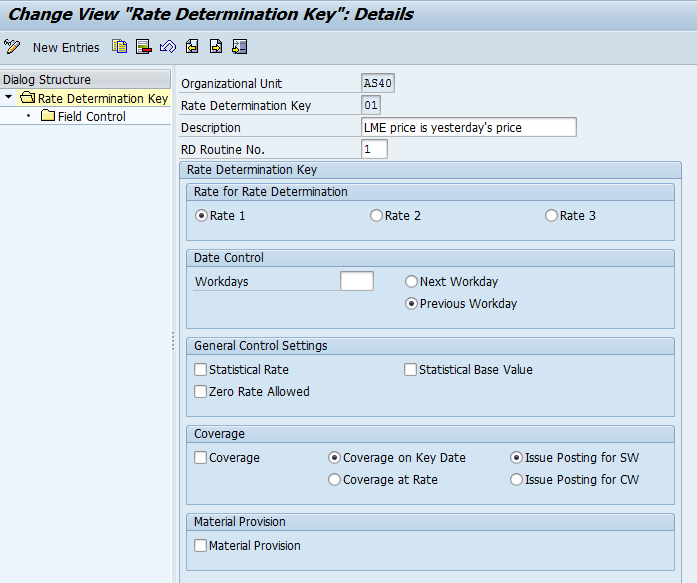

In sales document, as sales organization is already entered, user will select the rate determination key. Thus, relevant rate determination routine is known and according to the customizing above, a rate (either Rate 1, Rate 2 or Rate 3, whichever has been selected) will be found. A more detailed and understandable view of this customizing is as below in item level:

In this customizing, Field Control lets you control visibility/obligation of certain fields:

9. Sales order entry

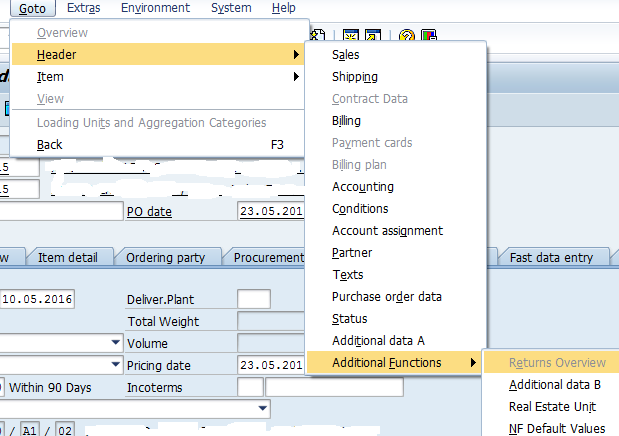

In sales order entry, if customer is relevant for LME (KNVV-J_1NBOESL) and there is at least one NF material in the order (NF key is filled for the distribution chain), unless you enter rate determination key, system won’t let you save the document. This is done via path Header -> Additional Functions -> NF Default values

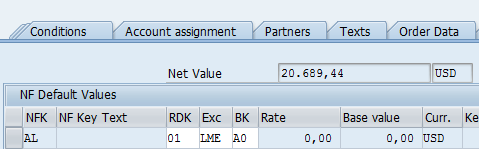

For the relevant NF key you enter the rate determination key, and then system calculates the price for your LME condition type according to the modules in your rate determination routine.

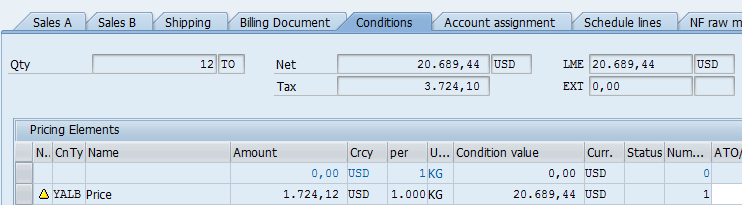

You can see from item level that price is calculated:

If salesperson fixes the LME price, you’ll need a separate condition type for this. This condition type should be a manual entry, and proper condition exclusion customizing needs to be done in order to make calculated LME price passive if manual LME price is entered in sales document.

Leave A Comment?

You must be logged in to post a comment.