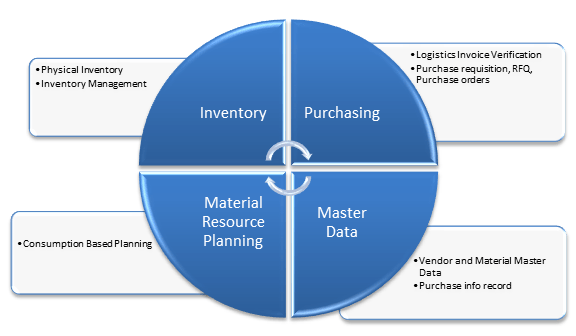

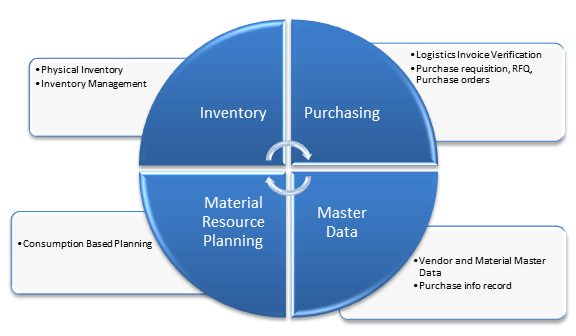

Materials Management module in SAP consists of several components and sub-components. The most prominent and widely used are Master Data, Purchasing and Inventory.

All of these components have their subcomponents that are essential in specific business processes, and all of the processes are executed by using transactions.

Transaction (in SAP) means processing of certain information in order to complete business process requirement. For example, if you have purchased 10 pieces of litter buckets, you can perform particular transaction code (t-code) that will reflect those changes in SAP. Most of the business processes involve multiple SAP transactions to be accomplished and are spread over one, two or more modules.

Transaction (in SAP) means processing of certain information in order to complete business process requirement. For example, if you have purchased 10 pieces of litter buckets, you can perform particular transaction code (t-code) that will reflect those changes in SAP. Most of the business processes involve multiple SAP transactions to be accomplished and are spread over one, two or more modules

Let’s briefly talk about the various sub-modules in SAP MM

Master Data

Data stored in SAP R/3 is categorized as

- Master Data and

- Transactional Data.

Master data is the core data that is used as a base for any transaction. If you are producing, transferring stock, selling, purchasing, doing a physical inventory, whatever your activity may be, it requires certain master data to be maintained.

Example of Master Data

- Material master data

- Customer master data

- Vendor master data

- Pricing/conditions master data

- Warehouse management master data (storage bin master data)

Learn more about Master Data here

Purchasing

Purchasing is a component of SAP MM module, and its process can be roughly depicted in below diagram.

MRP (material resource planning) creates procurement proposal and later gets converted into Purchase Requisition. Next step is assigning a source to Purchase Requisition, and release of Purchase Requisition. The PR gets converted to Purchase Order, and upon goods receipt, an invoice receipt can be done to complete the purchasing process. Additionally, payment is processed (in FI module).

Learn more about Purchasing here

Inventory Management

Inventory management is used to manage the inventory of the goods. It is based on several key processes like

- Definition of movement types

- Reservations

- Goods issue

- Goods receipt

There are a number of functions and transactions used in the Inventory management processes.

Learn more about Inventory Management here

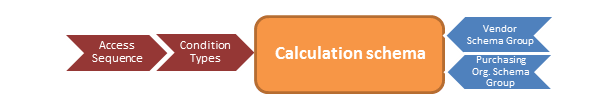

Pricing Procedure

Pricing procedure in MM module is a way to determine prices in purchasing documents. It gives us functionality to assign different calculation types for different needs. Defining a pricing procedure can be done by creating an access sequence, and assigning it to condition types. Access sequence tells the system where to look for the condition values.

Learn more about Pricing Procedure here

Leave A Comment?

You must be logged in to post a comment.