Introduction

This blog provides an overview of the key functionality of Production Planning and Detailed Scheduling in PP/DS for SAP S/4HANA.

For information about basic setting and basic customizing in embedded PP/DS refer to SAP note 2712349 – Best practices for implementation of Production Planning and Detailed Scheduling for SAP S… . You find details attached to the note on the doc ‘PPDS Cookbook 1709-1809-0102.pdf’.

This Blog Post is also valid for PP/DS for SAP S/4HANA 2020.

SAP Note “2952988 – Restrictions and Implementation Recommendations for Production Planning and Detailed Sched…” provides the latest release information for Production Planning and Detailed Scheduling as part of SAP S/4HANA 2020.

Regarding the Simplification List for PP/DS for SAP S/4HANA see SAP Note “2977528 – Simplification List: Production Planning and Detailed Scheduling for SAP S/4HANA 2020”

This blog is an overview description of functionalities and processes in embedded PP/DS and does not replace the SAP help nor the SAP Service notes

Target audience of the blog are project team members and key user who are interested in PP/DS or responsible for the implementation of production planning with SAP S/4HANA.

Overview

The overall planning process starts with the independent requirements. The demand program, which has to be covered by the production planning in the plant / MRP_Area, is determined using planned independent requirements from a demand forecast, sales orders or stock transfer requirements.

PP/DS for SAP S/4HANA supports various Manufacturing Models:

-

- Make to Stock

-

- Make to Order

-

- Make to Order with Order BOM

-

- Engineer to Order

-

- Project Manufacturing

-

- Flow Manufacturing

In SAP S/4HANA Demand Planning to generate forecasts as a future demand program is executed in Integrated Business Planning (IBP).

Integrated Business Planning (IBP) is an all-new implementation for Demand planning.

The SAP S/4HANA Sales & Operations Planning (SOP) will be replaced by Integrated Business Planning IBP (Functionality available in SAP S/4HANA delivery but not considered as future technology).

Refer to SAP note 2268064-S4TWL – Sales and Operation Planning

The Demand Planning SAP-APO-DP capabilities are partially available in SAP IBP for Demand.

Refer to SAP note 2456834 – Transition Guide for SAP APO

The way in which independent requirements behave in material requirements planning can be determined by their requirement type or by the requirements strategy.

The forecast consumption period is calculated in calendar days in PP/DS for SAP S/4HANA and in working days in SAP S/4HANA.

See also SAP note 2639404 – Forecast Consumption situation different in PP/DS and MD04 and section ‘Forecast Consumption’ of the note 2666947 – Restrictions and Implementation Recommendations for Production Planning and Detailed Sched…

Sales orders can be used as exclusive requirements sources (make-to-order production), or, together with planned independent requirements, they can create the total requirement.

Consumption with planned independent requirements is also possible.

Various requirements strategies are available, ranging from make-to-order production to make-to-stock production.

Make-to-Stock production:

-

- Planning at finished product level or assemblies

-

- Consumption with sales order od dependent requirements (for assemblies) possible

Final assembly based on sales order

-

- Planning at finished product level leads to procurement of assemblies for the finished product

-

- Final assembly only after a sales order is received

Make-to-order-production only

-

- No planning at finished product level

-

- Planning possible for assemblies

The material requirements planning (MRP) and capacity planning (CRP) can be executed in SAP S/4HANA Digital Core ERP-PP or embedded PP/DS.

While the basic production planning functions are available in the SAP S/4HANA Digital Core ERP-PP (MRP, CRP) embedded PP/DS provides additional advanced options for Production Planning and Detailed Scheduling.

In ePP/DS in PP – Production Planning orders are generated according to the required stock-/requirement situation and lot-sizing procedure (infinite order scheduling).

Based on the generated orders in Detailed Scheduling (DS) the orders and operations are fixed, scheduled according to production constraints (e.g. available capacity) and sequenced efficiently.

The PP (of ePP/DS) planning is executed by PP heuristics (dispatched within MRP_live) or processed using interactive tools (such as the product view)

The DS – detailed scheduling by DS heuristics or PP/DS Optimizer can be executed interactively using the Detailed Scheduling Planning Board or called as production planning run in background mode.

The planning in embedded PP/DS is always based on own master data (products, resources and PDSs) that must be integrated from the SAP S/4HANA Digital Core.

Master Data Overview

The following short summary gives an overview about main master data and the prerequisites for the master data relevant for PP/DS

Model and Planning Versions

Simulations in the PP/DS required the management of models and planning versions.

The active model 000 with planning versions 000 is used for the active planning.

The active planning version (000) in ePP/DS has to be created manually. You can create/use a planning versions other than ‘000’ for simulative planning. Only active models 000 are supported in PP/DS for SAP S/4HANA

The master data transaction data transferred from SAP S/4HANA to PP/DS are automatically assigned to the active model and the active Planning Version. (000)

Location

For setup and activation of Locations in ePP/DS execute the following reports to create and update locations in ePP/DS

-

- Create – /SAPAPO/CREATE_LOCATION for creating Business Partner location, Plant, MRP Area and Shipping Point.

-

- Update – /SAPAPO/UPD_LOC_SP_PL for updating Plant, MRP Area and Shipping Poin

Material / Product

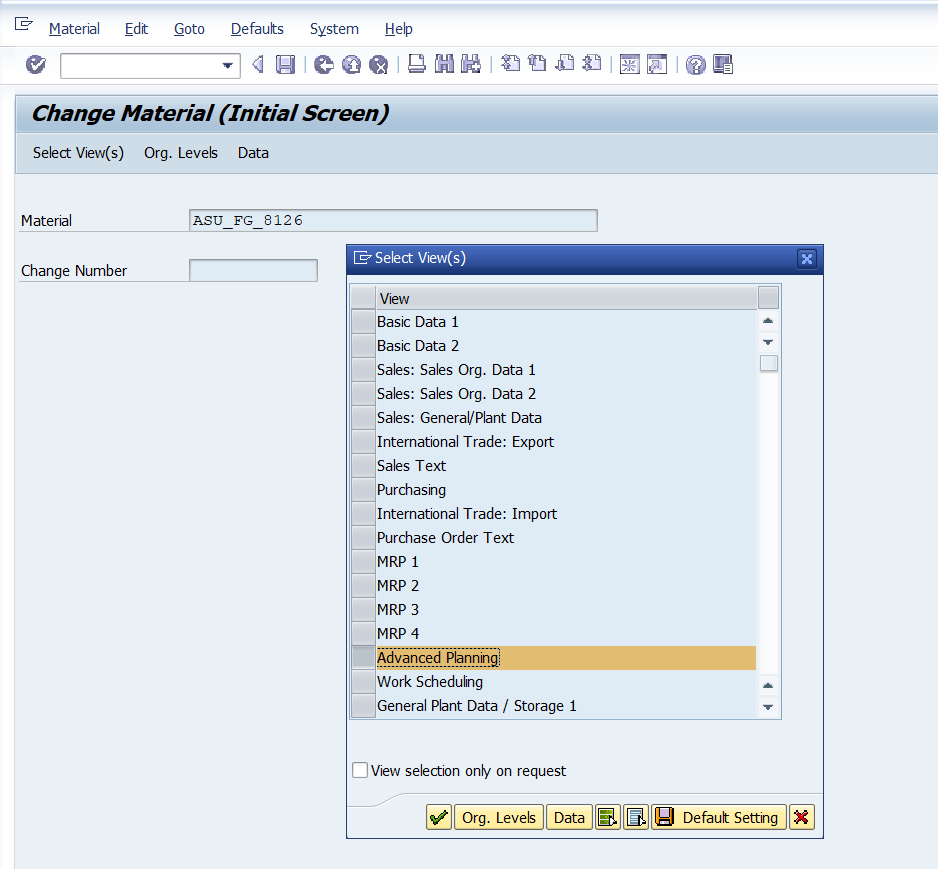

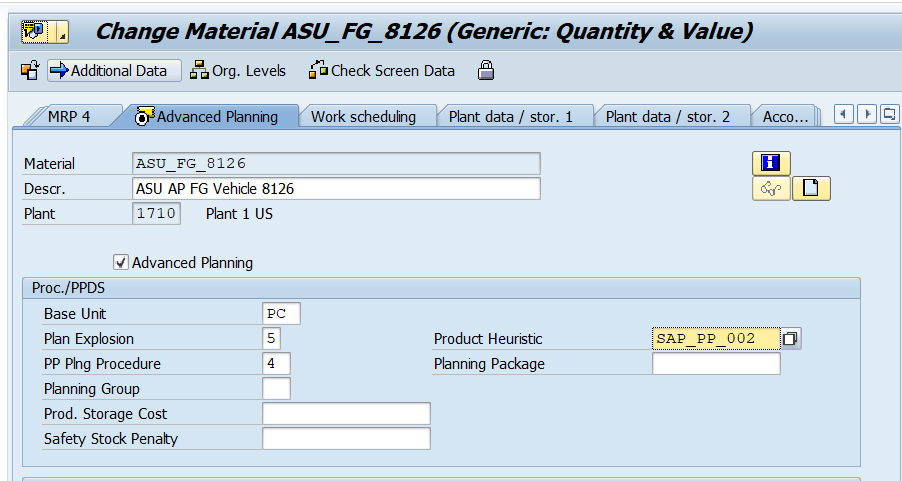

You activate a SAP S/4HANA Material for planning in embedded PP/DS by activation of the “Advanced Planning” checkbox in the “Advanced Planning” tab of the material master.

PP/DS for S/4HANA 2020 introduces a new planning status that is relevant for PP/DS for materials in the plant view. This enhances the use of the “Advanced Planning” indicator in such a way that this indicator can be removed from the material master record only under certain conditions.

For details refer to SAP note 2959476 – S4OP_2020_FPS0: Consideration redesign PPSKZ in PP/DS

Some PP/DS planning attributes can be maintained in the “Advanced Planning” tab of the material master. For other fields there is a standard mapping or a default value due to simplification.

The Advanced Planning Product Master is integrated into the SAP S/4HANA Material Master with CDS Redirects on material master.

The SAP S/4HANA production planning is not necessarily executed for all materials in embedded PP/DS.

Planning for critical materials may take place in ePP/DS. Materials that are running on bottleneck resources or with long replenishment times.

Less critical materials (such as consumption-controlled purchasing materials) may still only be planned in the SAP S/4HANA Digital Core ERP-PP.

It is recommended to use MRP type with following MRP Procedure “X Without MRP, with BOM explosion” for materials relevant to advanced planning.

For more information, refer to SAP Note 2342043 Integration of S/4 Product Master with SCM Product Master

The Advanced Planning product master is read-only master data for active version.

For simulation purpose you can change the product master attributes. They can only be changed in simulation versions. (Planning Version <> 000). Create local products in ePP/DS is not supported.

Work Center / Resource

SAP S/4HANA work centers or resources for which capacity planning is to take place in embedded PP/DS must also be integrated into ePP/DS by setting a flag “Advanced Planning” in the work center master data.

Setting the flag “Advanced Planning” within the work center master data triggers the initial and change transfer to ePP/DS resource master data

There are two options maintaining the available capacity for planning in Advanced Planning

-

- You can maintain the available capacity in ePP/DS. Only the header data for the work center capacity is transferred from SAP S/4HANA Digital Core to PP/DS.

Intervals of available capacity that exceed this overall capacity are maintained in ePP/DS

- You can maintain the available capacity in ePP/DS. Only the header data for the work center capacity is transferred from SAP S/4HANA Digital Core to PP/DS.

-

- The available capacity with intervals and shift pattern is maintained entirely in SAP S/4HANA-ERP as ’external capacity’ for planning in Advance Planning or APO-PPDS. Maintaining Intervals of available capacity that are in PP/DS is not possible.

To prevent data inconsistencies when you are also using the Fiori App Monitor Capacity Utilization the Capacity Variants, Shifts and Definitions are disabled in SAP GUI when External Capacity is selected for Resources

- The available capacity with intervals and shift pattern is maintained entirely in SAP S/4HANA-ERP as ’external capacity’ for planning in Advance Planning or APO-PPDS. Maintaining Intervals of available capacity that are in PP/DS is not possible.

For details refer to SAP Note 2598760 Enable Capacity Variants, Shifts and Definitions for

Resources with External Capacity in SAP…

Most of the resource master data does not need any maintenance in the ePP/DS resource master.

SAP recommends to use external capacities as much as possible.

Source of Supply (PDS for in-House production)

In SAP S/4HANA sourcing production versions are the only source of supply for in-house production.

The production version determines a manufacturing process by specifying a routing and a bill of material. Only production versions make sure BOM and routing fit together.

For more information refer to SAP Notes

2268069 – S4TWL – Simplified Sourcing

2267880 – S4TWL – BOM, Routing, Production Version

A Production Version is also required for phantom items.

In SAP S/4HANA several production versions can be defined in the material master (for example, for different lot size intervals). Each of these production versions is transferred to PP/DS as an individual PDS.

The initial transfer and update of the PDS is triggered by transaction CURTOADV_CREATE.

To schedule an operation from one alternative resource to another by drag & drop on the Detailed Scheduling Planning Board, in automatic rescheduling or optimization in case of overload, you have to add an alternative sequence to a routing with an alternative work center.

With the use of the BADI implementation CUSLNTRTO_ADDIN / CURTO_ALTERNATIV_SEQ alternative routing sequences will be displayed in alternative modes in the PDS.

This BADI can be activated in customizing under: Integration with Other SAP Components ® Advanced Planning and Optimization ® Application-Specific Settings and Enhancements à Enhancements for Production Data Structure à Change Production Data Structure

As alternative you can define resources as alternative modes in the PDS by classified work centers and operations in SAP-ERP.

( PP-PI doesn’t support alternative sequences so you can use classified work centers and operations for alternative modes in the PDS)

For details refer to SAP Note 576566-FAQ: Mapping of alternative resources in APO

(This note is also Valid for PDS)

You can also use the the BADI implementation CUSLNTRTO_ADDIN to define a custom developed solution for alternative resources / modes in the PDS or implement the SAP Consulting Solution

With a SCM Consulting Solution you can enhance the PDS CIF interface in a way that production alternatives modeled as Production Version in ERP are used as Alternative Modes in APO.

For details see SAP Note 2106976 – Alternative production version as alternative mode in PDS

Production Planning – MRP

If all prerequisites regarding basic settings and customizing are fulfilled and the master data required for planning is integrated from ERP of SAP S/4HANA Digital Core to embedded PP/DS the production planning in PP/DS can be executed.

The MRP procedure could be distinguished between material requirement planning and consumption-based planning.

In consumption-based planning, the procurement is triggered based on consumption values, the logic of these procedures is very simple. The consumption-based procedures of forecast-based and time-phased planning are not supported in ePP/DS.

The PP planning procedure in the product master describes how a product is to be planned.

Planning in the planning run is the “normal” setting, corresponding to the behavior in SAP S/4HANA-ERP.

It is recommended as a basic setting for all products.

Planning procedure 4 “Planning in Planning Run” for a product, the system will create a planning file entry for every planning-relevant change (you can adjust the events in customizing). The product is then planned in the next planning run, using the heuristic entered in the product master or Customizing.

The APO-PP/DS Standard PP planning procedures 3 (Cover Dependent Requirements Immediately) will not be supported in PP/DS for SAP S/4HANA.

(refer to SAP note 2647972 – Simplification List: Production Planning and Detailed Scheduling for SAP S/4HANA 1809)

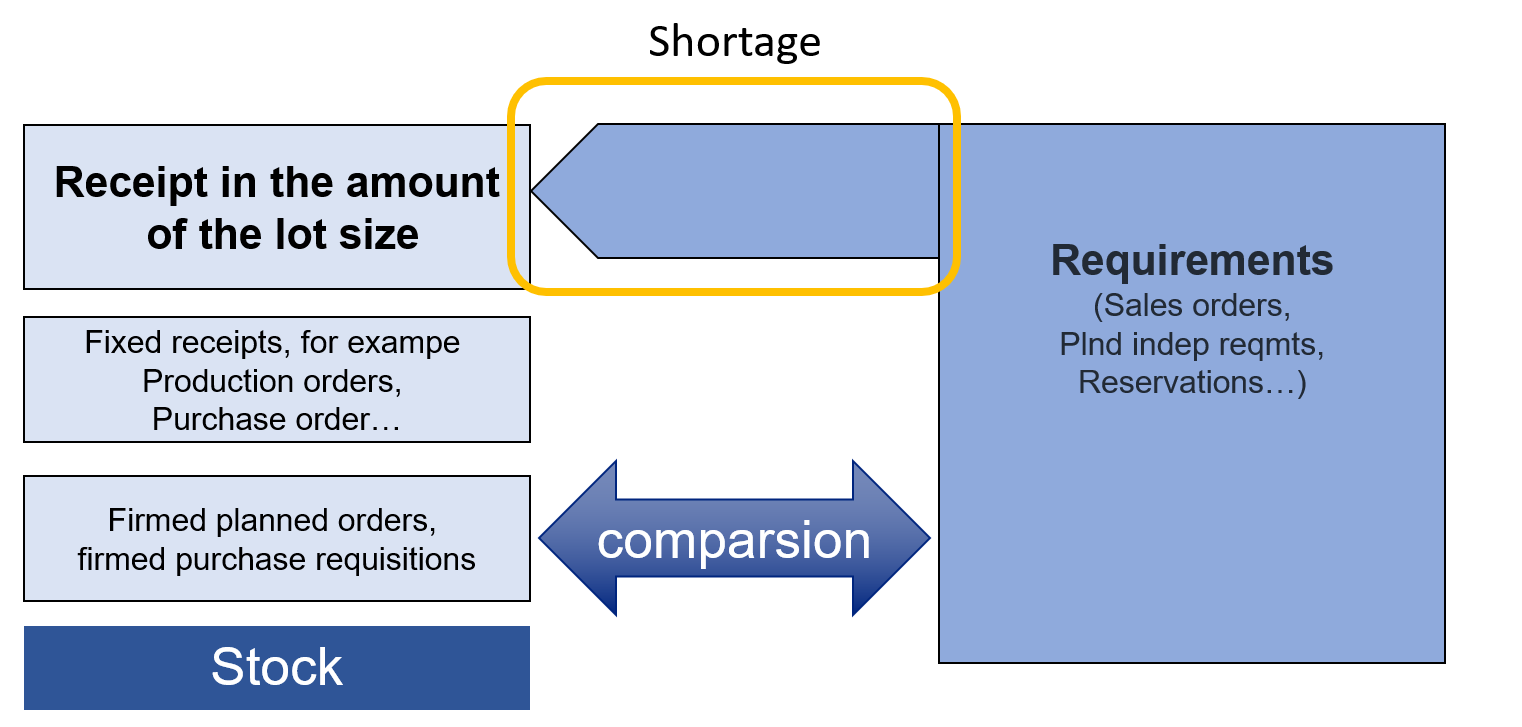

Production planners have to make sure material is available when needed. The MRP run determines expected material shortages and creates planned orders, purchase requisitions, or delivery schedule lines to cover the expected material shortages.

In SAP S/4HANA the MRP Live (MD01N) is a new MRP run optimized for SAP HANA.

Trigger of MRP for SAP S/4HANA ERP- Materials and Advanced Planning (PP/DS) Materials in ONE transaction the MD01N.

In SAP S/4HANA only single MRP run has to be scheduled for SAP S/4HANA-ERP and Advanced Planning Materials.

The Low-level code calculation happens for all materials, whether those are relevant to PP/DS (Advanced Planning) or not, in SAP S/4HANA through MRP Live

MRP Live reads material receipts and requirements, calculates shortages, and creates planned orders and purchase requisitions all in one database procedure.

The SAP S/4HANA Classic MRP is still available as an interim solution (Functionality available in SAP S/4HANA on-premise but not considered as future technology.)

For details refer to SAP note 2268085 – S4TWL – MRP live on SAP HANA – MD01N

All downstream materials should be Advanced Planning-relevant if planned together with MRP Live.

This means the data modelling should be such that once a material at one BOM level is PP/DS-relevant then the materials above that BOM level should also PP/DS-relevant (Advanced Planning-relevant). This is to ensure that depended demands are also in liveCache of ePP/DS.

The MRP-based DS functionality with Material Requirement Planning in ERP on SAP S/4HANA is not supported.

Refer to SAP note 2666947 – Restrictions and Implementation Recommendations for Production Planning and Detailed Sched…

The result of the production planning are procurement elements that are used to cover the

existing requirements.

Planned orders are created for in-house production. These orders are converted into manufacturing orders at a later process.

Purchase requisitions are created for external procured products. The requisitions have to be converted into purchase orders. Scheduling agreement schedule lines can also be created immediately.

The Advanced Planning can be executed as interactive single-Item for a product or as total planning for a group of products that may be freely defined (e.g. all products from a plant)

The total planning can be executed in SAPGui or FIORI Launchpad online or scheduled in a background Job.

In online planning, the production planning run is executed immediately. This procedure is ideal for low data quantities.

The interactive planning in ePP/DS can be carried out from the product view, product planning table, and the detailed scheduling planning board or by the new MRP Apps like “Monitor Material Coverage” & “Manage Material Coverage” in the FIORI Launchpad.

For more information about Fiori Apps in Material Requirements Planning (PP-MRP) see the documentation à Fiori Apps in PP-MRP

Heuristics

In ePP/DS the Material Requirements Planning and Detailed Scheduling is performed by heuristics.

A heuristic is a planning function that executes planning for selected objects (in this way, the focus of planning can be products, orders, operations, resources, or line networks) using a particular algorithm

In the standard version of PP/DS for SAP S/4HANA, a range of heuristics are available for various tasks in Production Planning and Detailed Scheduling.

You can choose between standard algorithms to solve specific planning tasks. You can vary particular settings of each algorithm and in this way use the same algorithm for different heuristics. It is possible to use SAP algorithms to define your own heuristics. You even can develop your own heuristic in custom code.

Heuristics:

-

- Heuristics are selected and used in planning based on the context.

-

- A heuristic is a planning function that you can use to plan selected objects

-

- Heuristics offer a wide range of planning functions and can be used in background planning and interactive planning

-

- In the standard version of Advanced Planning in SAPS/4HANA (e//PDS), a range of heuristics is available for various tasks in Production Planning and Detailed Scheduling.

-

- It is possible to use SAP algorithms to define your own heuristics by your own settings in the additional control parameters or create a user-programmed heuristic

In this blog not all heuristics are discussed in detail. This Blog focus on describing the most important heuristics for Production Planning and Detailed Scheduling.

SAP standard heuristics are available in the following areas:

-

- Production planning:

This heuristic is mainly for lot-sizing procedures with planning focus on the products.

- Production planning:

-

- Detailed scheduling:

These heuristics are for scheduling; their planning focus is on resources and operations. Examples of such heuristics are reduce lead-time and dissolve backlog

- Detailed scheduling:

Heuristics in Production Planning / Product Heuristics

The heuristics most relevant for Planning are highlighted in the following Picture

The SAP_PP_002 “Planning of Standard Lots” heuristic is used to set “normal” planning for a product.

The service heuristics are primarily used in the context of capacity planning and optimization, that is, in the step after material requirements planning.

Heuristics are used in interactive planning, the SAP S/4HANA Digital Core MRP_live or in the Advanced Planning (PP/DS) production planning run.

In the Advanced Planning you can execute several heuristics, which belong to both production planning and detailed scheduling, for the same products in one planning run.

The APO-PP/DS MRP2-heuristic (SAP_MRP_002 – Product planning (Plan comp. immediately) and Heuristic related to CTP processes are not supported by ePP/DS on SAP S/4HANA.

The heuristics SAP_PP_003 – Planning shortage quantities is also not available in standard. However multilevel planning can be used without CTP process using custom specified planning procedures and heuristics.

(refer to SAP note 2647972 – Simplification List: Production Planning and Detailed Scheduling for SAP S/4HANA 1809

On the Advanced Planning tab page in the SAP S/4HANA Material master, you specify a heuristic for product planning in PP/DS for SAP S/4HANA, if the product is not to be planned using the standard heuristic defined in Customizing.

In the planning procedure in Customizing, enter the standard product heuristic that you want to use to plan the products for which no heuristic has been defined in the product master.

This Planning Procedure can be maintained in customizing under: Advanced Planningà Maintain Planning Procedures

The product heuristic entered in the material master controls the planning of this product in the material requirement planning run. Lot-sizing procedures can be implemented using these heuristics.

Service Heuristics (Service Functions)

The service heuristics are primarily used in Detailed Scheduling in the context of capacity planning and optimization following to the material requirements planning.

MRP_live will not perform Service Heuristics. So it is necessary to coordinate the production planning with MRP in MRP_live and detailed scheduling in Advanced Planning.

Heuristics for detailed scheduling are used to schedule selected operations on resources and dates.

In the production planning run and the planning board the DS Heuristic schedule operations a particular sequence, resolve backlog or adjust capacity overload.

See also SAP Help: Example: Heuristic Settings for the MRP Process

The following detailed scheduling heuristics are used to determine dates/times and resources for operations.

In the Fiori App “Production Scheduling Board” the following standard heuristics are supported:

-

- SAP001 – Schedule Sequence

-

- SAP002 – Remove Backlog

-

- SAP003 – Schedule Sequence Manually (Fiori UI pop-up supported)

-

- SAP004 – Minimize Runtime

-

- SAP005 – Schedule Operations

-

- SAP_DS_01 – Stable Forward Scheduling

-

- SAP_DS_02 – Enhanced Backward Scheduling

-

- SAP_DS_03 – Change Fixing/Planning Intervals

-

- SAP_DS_04 – Activate Seq.-Dependent Setup Activities

Additional heuristics in the are also supported in “Production Scheduling Board” if the heuristics are configured to be executed in the background, without a user interface.

The objective of a production planning run is generally to create a feasible production program. The actual planning is normally broken down into several steps, like in the follwoing sample process:.

-

- Normal material requirements planning is carried out with the MRP_live in ERP on SAP S/4HANA or on ePP/DS carried out with the SAP_MRP_001 heuristic.

Both planning’s are executed infinitely.

- Normal material requirements planning is carried out with the MRP_live in ERP on SAP S/4HANA or on ePP/DS carried out with the SAP_MRP_001 heuristic.

-

- In order to link the created structure of requirements and requirement coverage elements with each other on multiple levels a heuristic for creating fixed pegging is used.

-

- The capacity planning step can be carried out with the optimizer, which, in addition, can carry out simultaneous sequencing with regard to setup times

-

- The rest of the components, not relevant for Advanced Planning, on lower low-level are planned in the SAP S/4HANA MRP_live

Production Planning

In this Blog there is no need to discuss the PP/DS concept of Net Requirements Calculation and Lot-Size Calculation in detail.

For this Blog, it is only important that Net Requirements Calculation and Lot-Size Calculation created procurement elements.

The procurement element is procured based on the lot-sizing procedure.

The production dates are determined by exploding the production data structure (PDS) and then carrying out lead time scheduling.

PDS Explosion and Scheduling will be a topic of a separate blog

Pegging

Pegging is used to assign suitable existing product receipts and product stocks, which can cover the requirement, to a product requirement. Pegging organizes the material flow through all BOM levels, from the procurement of components and raw materials to delivery of a sales order, for example.

Orders that are linked together, and their pegging relationships, form a Pegging structure.

The picture below gives an example of a pegging structure. The arrows represent the pegging relationships; that is, the material flow

Pegging be used by subsequent procedures.

Based on pegging relationships, the system can:

-

- Identify planning problems on various production levels and display them using alerts

-

- Automatically forward scheduling specifications for an order to the dependent orders in the pegging structure, in Detailed Scheduling

-

- Optimize delays and storage costs in PP/DS optimization

There are two different types of pegging relationships: fixed and dynamic.

Fixed pegging enables you to fix a pegging relationship. The fix pegging relationship will not be changed automatically by the system.

For pegging relationships to be created, the product, location, account assignment (make-to-stock and make-to-order production) and planning version must be the same.

For details refer to SAP help: Pegging

Pegging should not be confused with the net requirements calculation: During planning, using the net requirements calculation, the system identifies shortages in order to then create receipts to remove these shortages. If the MRP has taken place, a pegging network will be established based on it.

When the Production planning has been executed the planned orders are converted into production orders.

PP/DS for SAP S/4HANA planned orders already contain all production dates. The corresponding planned orders in ERP on S/4HANA, however, do not contain operation dates, but rather basic dates between which production should take place. In fact planned orders in ERP have no operations.

Planned order in ERP on SAP S/4HANA contain the all dependent requirements for both Advanced Planning and non-Advanced Planning components.

To ensure consistency of the availability dates and requirements dates between PP/DS and ERP on SAP S/4HANA, all components and items of a planned order should be integrated with ePP/DS for which the requirements dates and availability dates that have been planned using detailed scheduling are required based on the dates of the assigned operations. In this case, the availability dates determined by Advanced Planning are also transferred to ERP on S/4HANA.

For components that are non-Advanced Planning -relevant the ‘Adjust basic dates, dependent requirement on order start date’ should be selected for changing the date in the Customizing of the scheduling parameters for the order type for planned orders (transaction OPU5). The requirements dates and availability dates are defined by the order start date.

COMMENT: In this case where detailed scheduling takes place in Advanced Planning (ePP/ DS) you should not use lead time scheduling to calculate the requirements dates and availability dates of components that are not Advanced Planning -relevant (for example, using the modification from note 161028) and simultaneously setting the secondary requirements to the operation dates in the scheduling parameters for the order type for planned orders (transaction OPU5).

For details refer to SAP Note 785903-Requirements and availability dates for planned order

A common misunderstanding is that the capacities defined in the lead time scheduling can transfer the dates of the ePP/DS operations, or that work center changes carried out in ePP/DS can be copied to the specification of capacities for the lead time scheduling. However, this is not the case because the ERP on SAP S/4HANA planned orders do not have any operations and thus no operation integration, as is possible with manufacturing orders.

The operations in ERP Planned Orders are the operations of the Standard sequence scheduled to the Basic dates.

In SAP S/4HANA there is a single conversion report for both ERP and PP/DS for SAP S/4HANA planned orders

Covert Planned orders in SAP S/4HANA (ERP and PP/DS)

to Production Orders with report /SAPAPO/PROD_ORDER_CONVERT

and Planned Orders to Process Orders with report /SAPAPO/PROC_ORDER_CONVERT

These reports ensure a synchronous and queue-less update of converted orders across ERP and Advances Planning in SAP S/4HANA.

Product View:

The Material requirements planning in PP/DS is usually evaluated from the product view.

The product view is a current overview of the stock, receipts, and requirements for a product in a specific location for a specific planning version.

Alerts can draw your attention to problem situations.

The product view contains a large number of different evaluation tools. In addition, planning can be changed interactively.

A further tool for Interactive Planning in ePP/DS is the Product Planning Table.

The extremely flexible product planning table provides advanced planning options and is especially suitable for repetitive manufacturing

The SAP Help table lists “Tools for Interactive Planning “ that feature planning functions to display various views of the planning.

SAP Help: Production Planning and Detailed Scheduling (PP/DS) à Interactive Planning à Tools for Interactive Planning

https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.001/en-US/234617503ebcbc10e1000000…

Detailed Scheduling Planning Board

The most important tool in capacity planning is the detailed scheduling planning board.

The Detailed Scheduling planning board is the central tool for interactive capacity planning. In the individual charts of the Detailed Scheduling planning board, different time-based aspects of planning are represented graphically.

These include the time situation of operations on resources, the time-based development of the resource load or pegging relationships. Numerous planning activities are executed with the help of the planning board. The result of the planning does not have to be adopted by production. It can also be saved as a simulation version at first.

The layout of the planning board can be defined very flexible, for example:

-

- The different charts (for example, a resource chart and an order chart)

-

- The field selection and sorting for the columns in the table section of a chart

-

- The format of the rows in the table section

-

- The objects displayed in the diagram section of a chart, for example:

-

- Operations or orders (graphical objects)

-

- Histograms (curves for warehouse stock and resource utilization)

-

- Network views of operations and orders that show the time and pegging

-

- relationships between operations and orders

-

- The layout of operations and orders in the diagram section

In the planning table, you can reschedule operations and orders by a DS heuristic or manually using Drag & Drop.

You can change the planning situation by: changing resources (capacity, work times, and so on) or changing orders (quantities, data).

Functions in Detailed Scheduling Planning Board

If you need more detailed information on the DS planning board, see the online help.

SAP Help: Production Planning and Detailed Scheduling (PP/DS) à Interactive Planning à Scheduling with the Detailed Scheduling Planning Board

Reporting lists are available to show an overview of the current planning situation.

A number of different evaluations are possible; from the view of the resources, the orders, or the operations, for example.

These Report lists can be called up from the SAP menu or the DS planning board.

-

- Order list: For selected resources, the system displays a list of all orders with the first operation that is processed using one of these resources.

-

- Operation list: For selected resources, the system displays a list of operations with components that are processed using these resources.

-

- Production overview: A list for selected products.

-

- WIP list: Displays the stocks for the selected resources that are provided in the operations for further processing.

-

- Resource utilization: This displays the resource utilization for single resources or multiple resources selected for each period.

PP/DS Optimizer

The optimizer covers a wide range of production planning functions and therefore cannot be described comprehensively in this Blog. In this Blog you will gain an overview about the PP/DS optimizer

The purpose of optimization is to generate feasible production plans and increase the efficiency of production.

Several optimization parameters (such as setup times, due date violations) can be weighted in such a way that the optimized schedule comes as close to the desired results (for example, minimum setup times) as possible.

The Optimization allows to optimize the production dates/sequences and the resource assignment of existing operations/activities that were previously generated by the production planning run or manual planning.

The purpose of optimization is to generate feasible production plans and increase the efficiency of production. Several optimization parameters (such as setup times, due date violations) can be weighted in such a way that the optimized schedule comes as close to the desired results (for example, minimum setup times) as possible.

The following parameters can be taken into account in optimization:

-

- Production span (from the start of the first operation to the end of the last operation in a schedule within the optimization horizon). The production span makes a statement about the compactness of the orders within the optimization horizon.

-

- Sum of setup times

-

- Sum of setup costs

-

- Maximum delay costs (maximum delay of an order compared to its requirement date or its due date).

-

- Sum of delay costs (delay compared to requirements or due dates)

-

- Sum of mode costs through alternative modes.

Optimization is integrated in the following applications:

-

- Detailed Scheduling Planning Board

-

- Product Planning Table

-

- Production Planning Run

You execute the optimization interactively in the planning tables (detailed scheduling planning board and product planning table), and in the background for the production planning run.

Alert Monitor

The Alert Monitor is a monitoring Tool that provides the planner pointed information and access to problem situations in production planning in ePP/DS. The purpose of the Alert Monitor is to inform the planner of exception. It is also possible to send alerts by mail.

The Alert Monitor provides a range of predefined alert types.

To use the Alert Monitor to monitor production planning in PP/DS, you must define an alert profile for the application.

For different alert profiles, you can select the alerts you want to see from a list of predefined alert types and define different thresholds for

-

- Error (priority one, highlighted in red)

-

- Warning (priority two, highlighted in yellow)

-

- Information (priority three, highlighted in white)

For more information see SAP Help : Production Planning and Detailed Scheduling (PP/DS) à Alert Monitor

https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.001/en-US/47f925c8852f383ce1000000…

For Alert type and groups see Production Planning and Detailed Scheduling (PP/DS) à Monitoring of PP/DS Alerts.

For Tips and Tricks for Handling Alert Monitor refer to SAP Note 495166

I close the Blog by reminding SAP Note 2963990 – Release Information Note: Production Planning and Detailed Scheduling for SAP S/4HANA 2020 with release information for Production Planning and Detailed Scheduling for SAP S/4HANA 2020.

I hope you enjoyed this blog and gained an overview about the key functionality of

Production Planning and Detailed Scheduling in embedded PP/DS for SAP S/4HANA.

Leave A Comment?

You must be logged in to post a comment.