Introduction

The purpose of this blog is to describe the general configuration steps in the SAP S/4HANA Embedded EWM that are required to complete the configuration for the warehouse process setup of the Advanced Production Integration process.

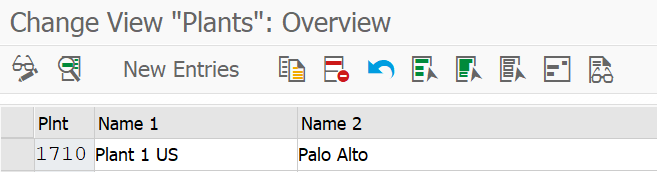

Organization Structure

| IMG Menu

(SAP EWM) |

Enterprise Structure → Definition → Logistics -General → Define, copy, delete plant |

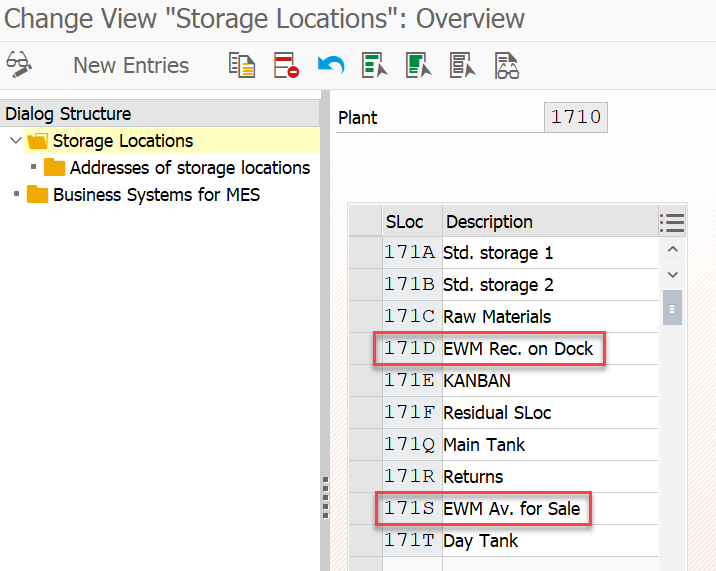

| IMG Menu

(SAP EWM) |

Enterprise Structure → Definition → Material Management → Maintain storage location |

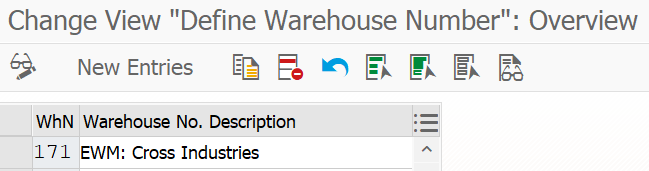

| IMG Menu

(SAP EWM) |

Enterprise Structure → Definition → Logistics Execution→ Define, copy, delete, check warehouse number |

| IMG Menu

(SAP EWM) |

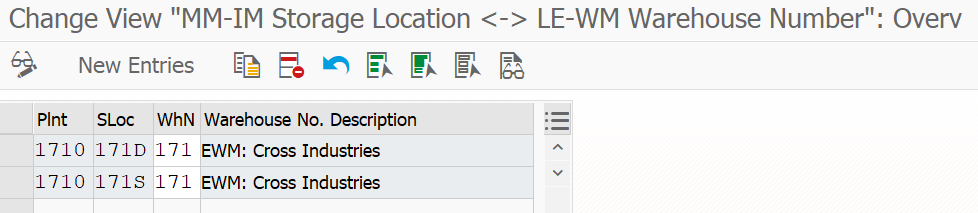

Enterprise Structure → Assignment → Logistics Execution→ Assign Warehouse Number to Plant and Storage Location |

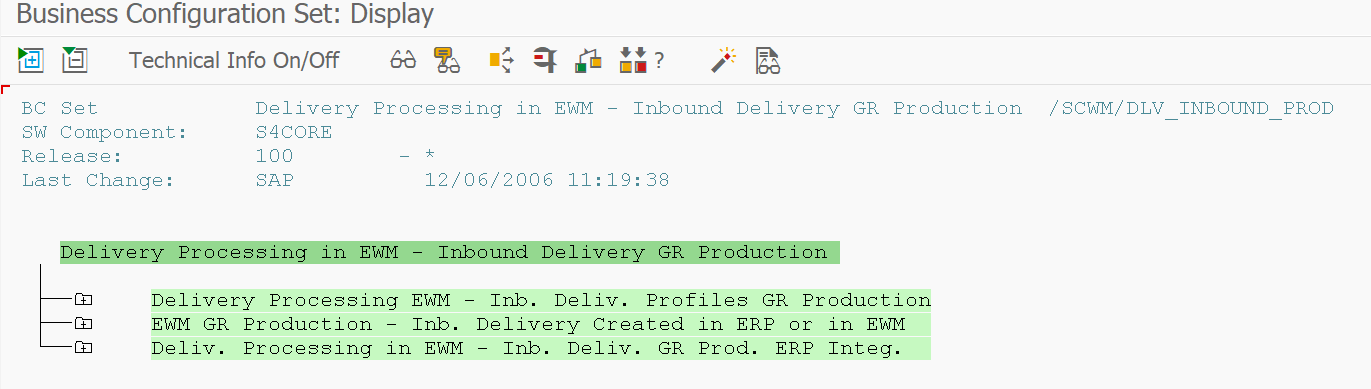

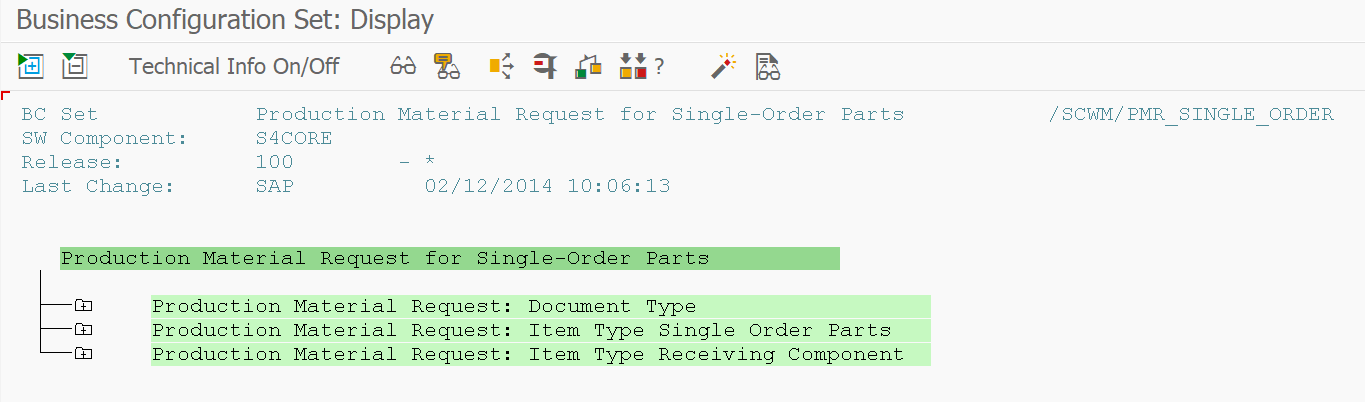

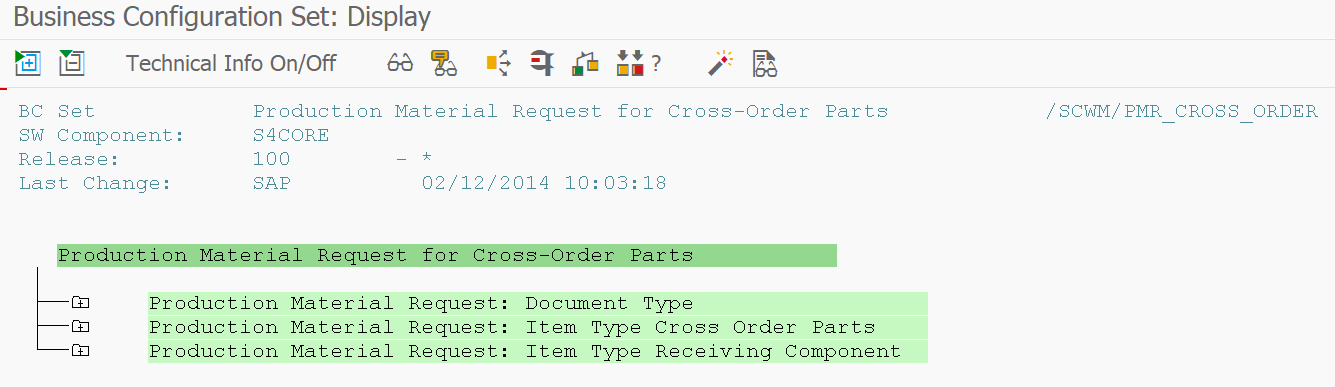

Activation of BC Sets

This procedure uses BC Sets to make necessary standard settings for the Advanced Production Integration process.

| Easy Access Menu

(SAP EWM) |

Tools → Customizing → Business Configuration Sets → Activation Of BC Sets |

| Transaction Code | SCPR20 |

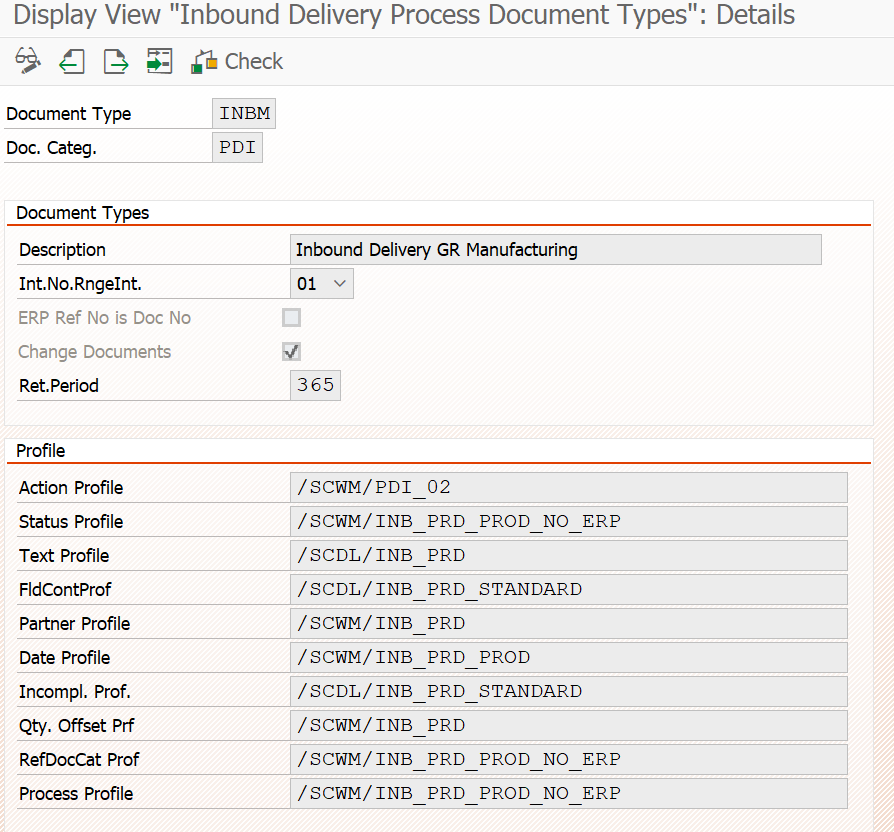

Internal Number Range Setting for Inbound Delivery Type “INBM”

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Inbound Delivery → Define Document Types For Inbound Delivery Process |

Warehouse Structure

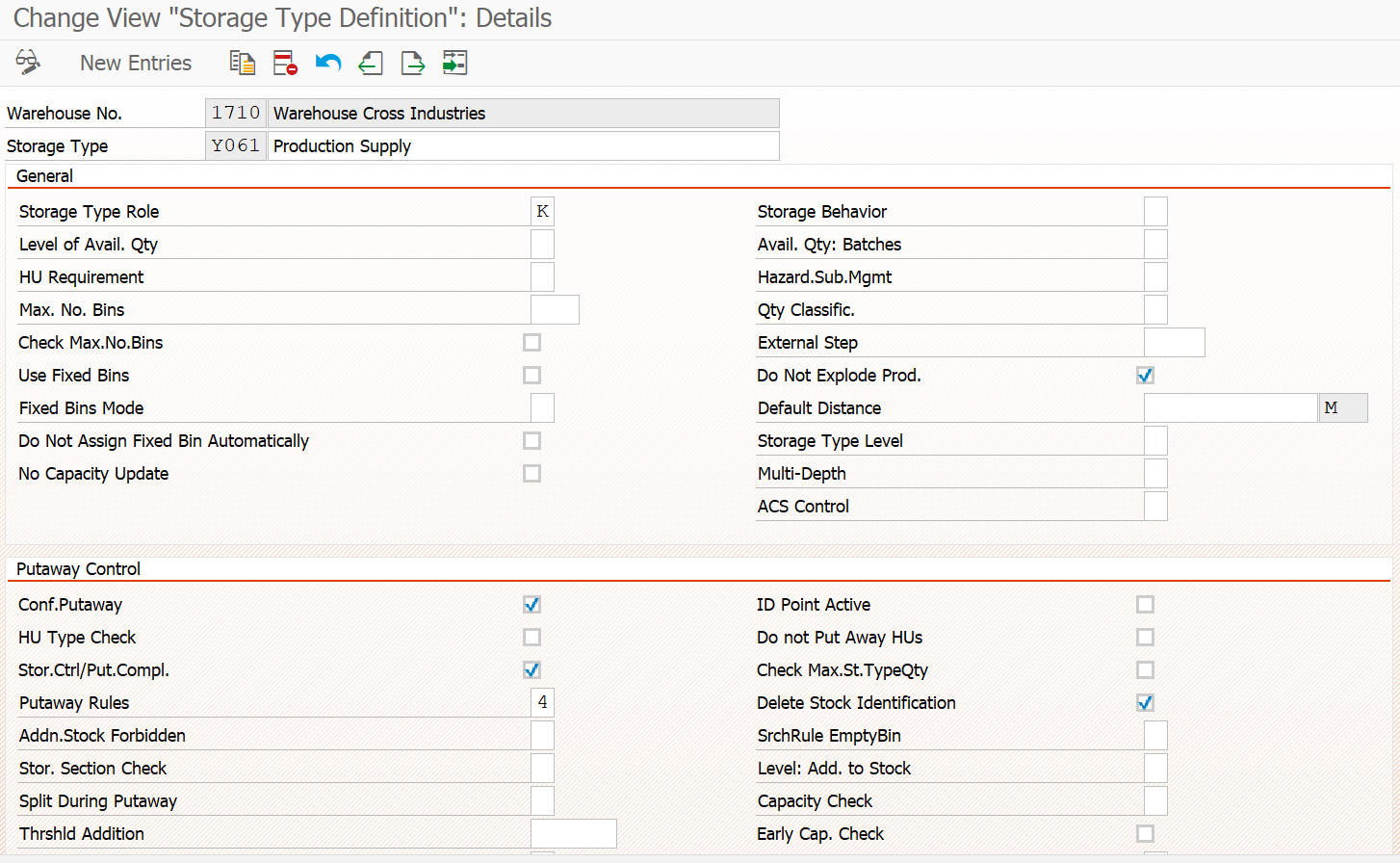

Define Storage Type

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Define Storage Type |

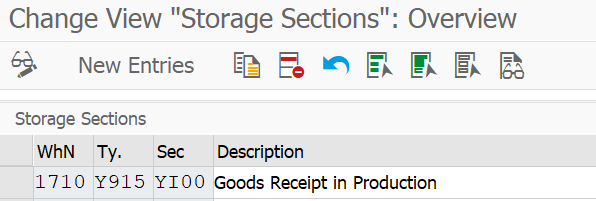

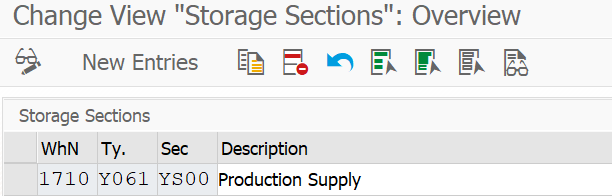

Define Storage Sections

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse → Management → Master Data → Define Storage Section |

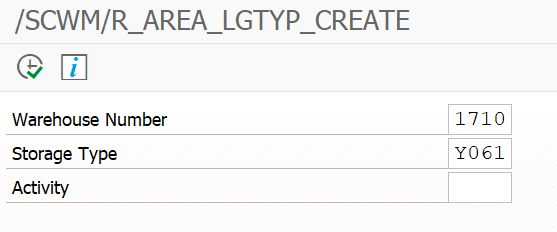

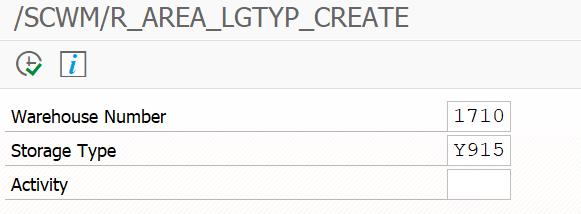

Generate Activity Areas from Storage Type

The purpose of this activity is to generate activity areas for the corresponding storage types.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Activity Areas → Generate Activity Area From Storage Type |

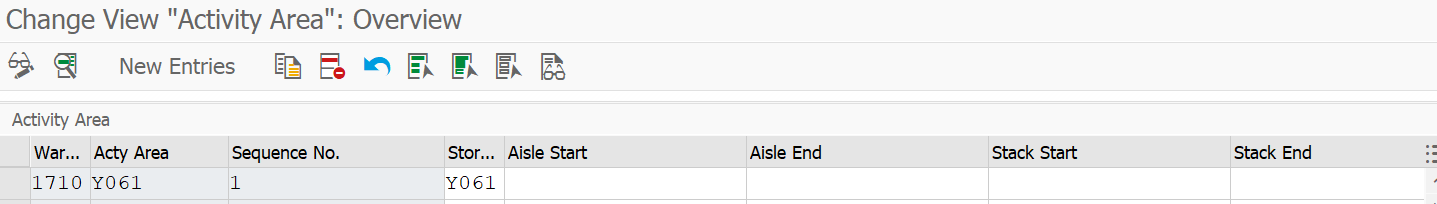

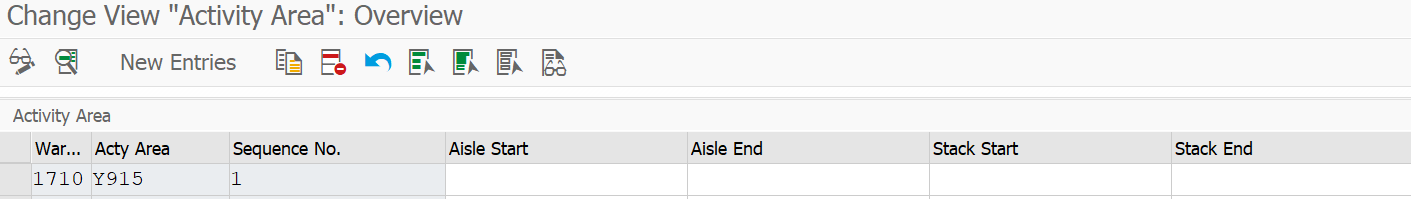

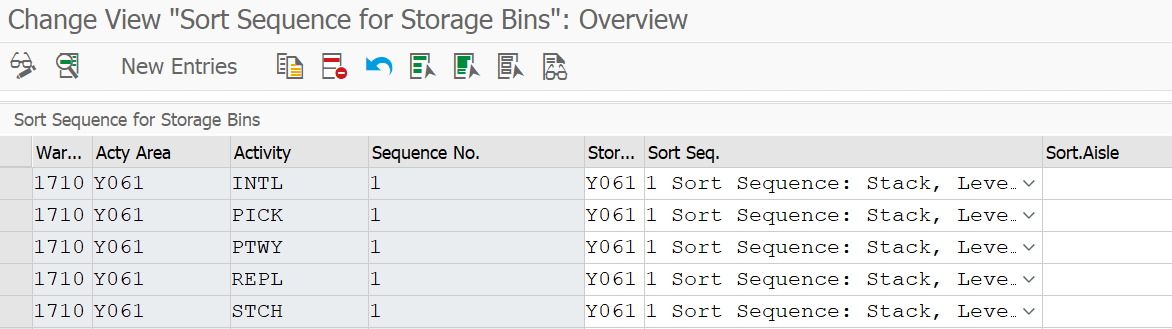

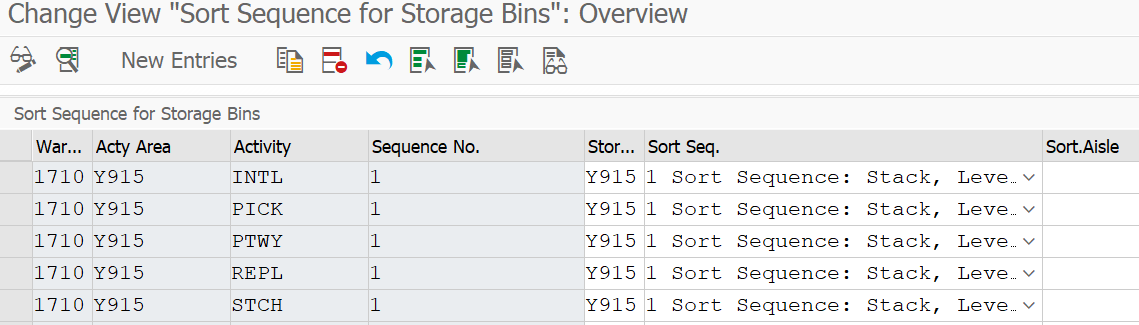

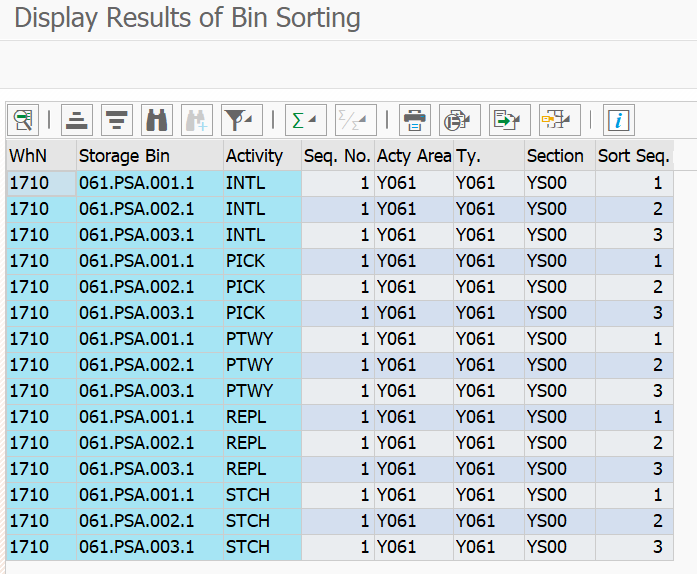

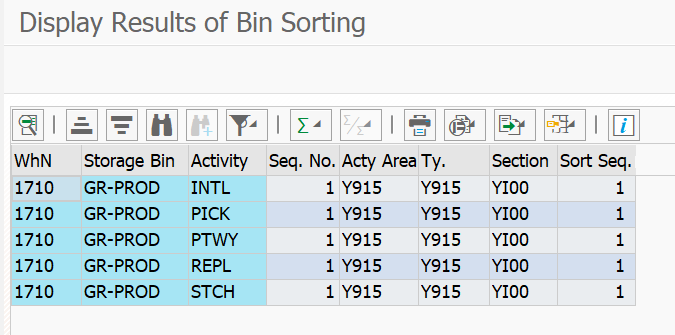

Once you have generated an Activity Area for all activities, a generic sort sequence is automatically created for every combination of storage types:

-

- Y061

-

- Y915

and activities:

-

- CLSP

-

- INTL

-

- INVE

-

- PICK

-

- PTWY

-

- REPL

-

- STCH

Assign Storage Bins to Activity Areas

The purpose of this activity is to assign storage bins to the newly created Activity Areas.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Activity Areas → Assign Storage Bins to Activity Areas |

Define Sort Sequence for Activity Area

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Activity Areas → Define Sort Sequence For Activity Area |

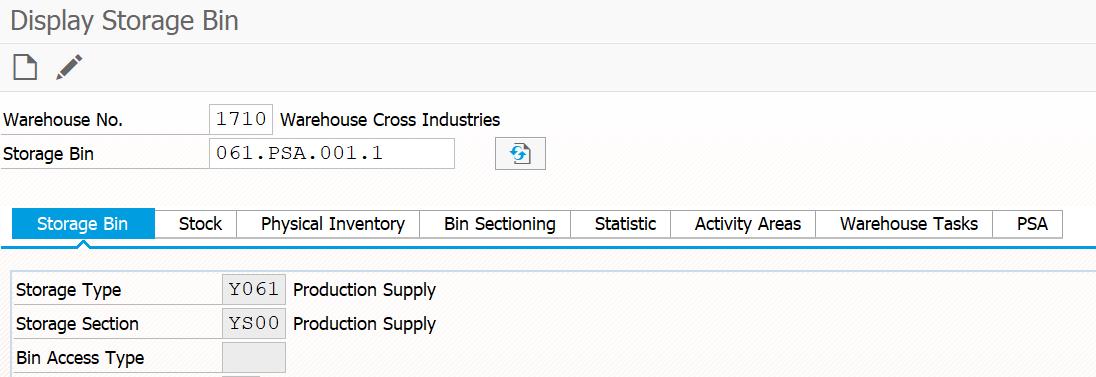

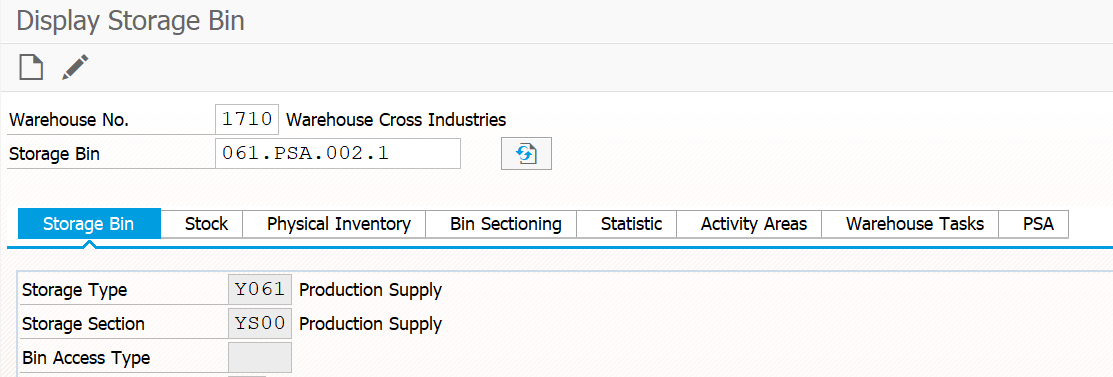

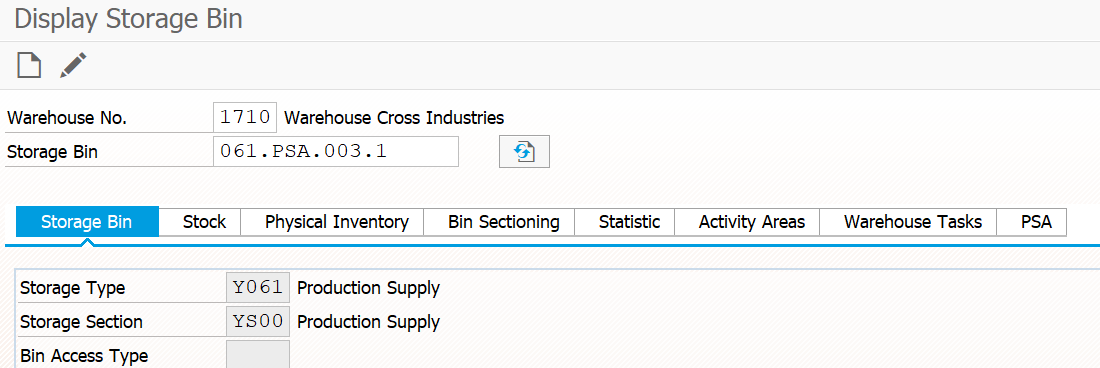

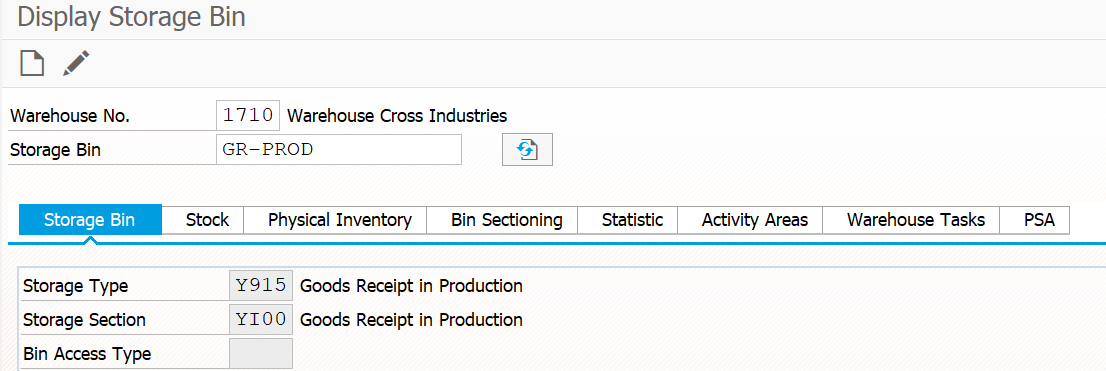

Manual Creation of Storage Bins

| Easy Access Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Storage Bin → Create Storage Bin |

| Transaction Code | /SCWM/LS01 |

Sort Storage Bins

| Easy Access Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Storage Bin → Sort Storage Bins |

| Transaction Code | /SCWM/SBST |

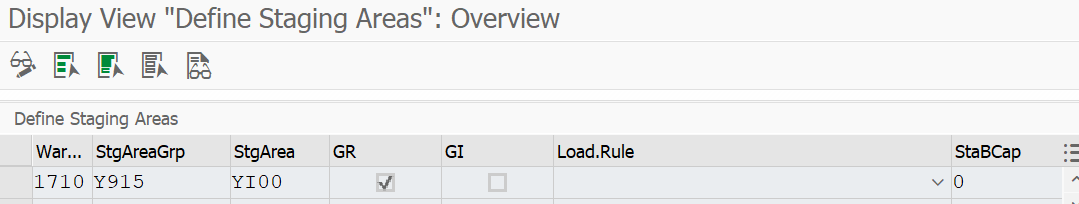

Define Staging Areas

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Staging Areas → Define Staging Areas |

The purpose of this activity is to create staging areas for the warehouse number 1710.

In the system, a staging area is defined by a storage type (called staging area group), a storage section (called staging area), and one or several storage bins (called staging bays).

Additionally, it must be defined as staging area in the system. A staging area can be assigned to one or several doors.

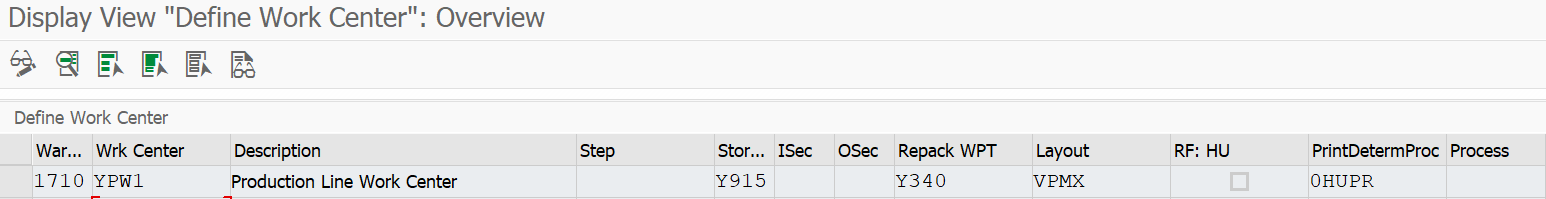

Define Work Center

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse → Management → Master Data → Work Center → Define Work Center |

Configure Production Material Request Creation in EWM

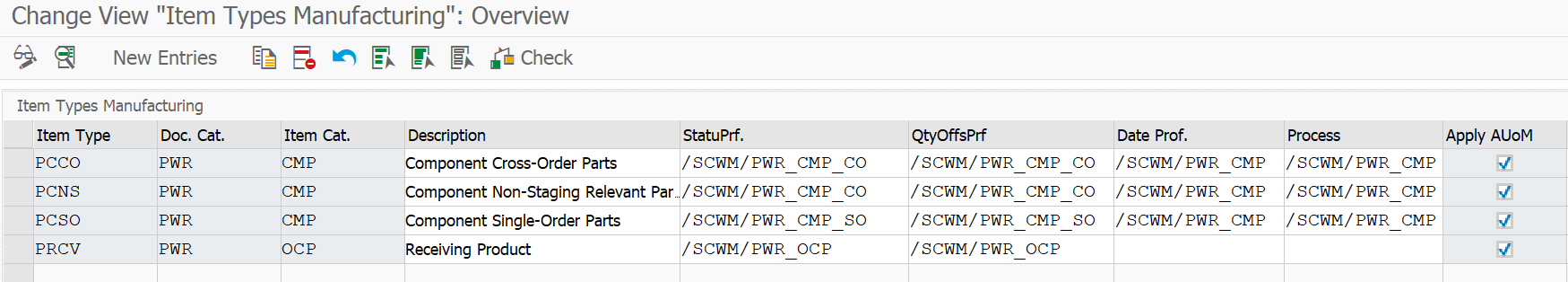

Define Item Types for Production

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Issue Process → Production Material Request → Define Item Types for Production |

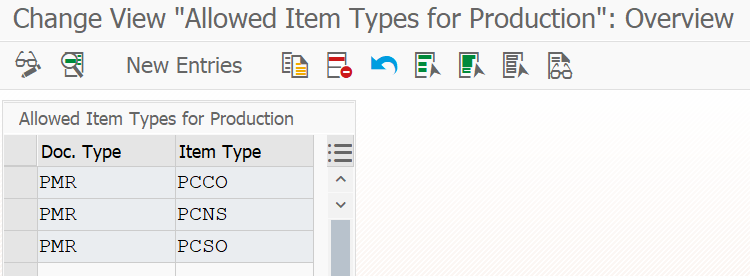

Define Allowed Item Types for Production

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Issue Process → Production Material Request → Define Item Types for Production |

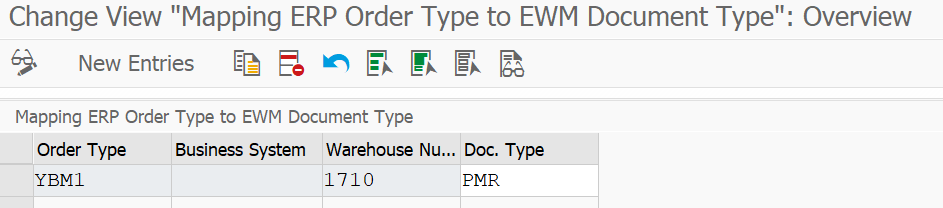

Map SAP ERP Order Type to SAP EWM Document Type

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Interfaces → ERP Integration → Production → Map SAP ERP Order Type to SAP EWM Document Type |

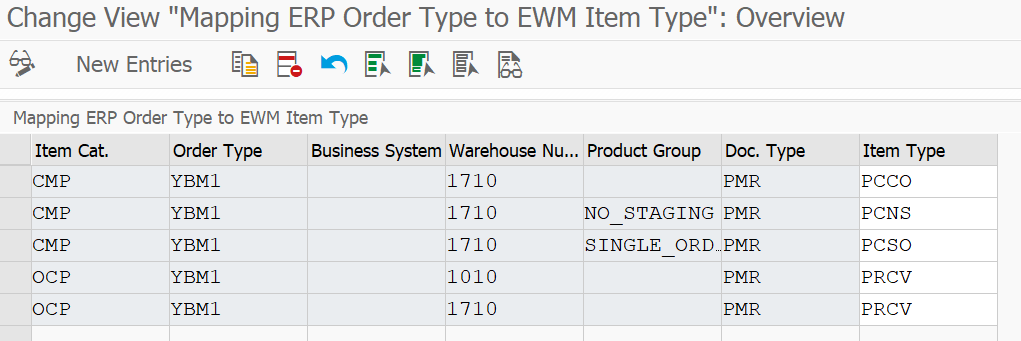

Map SAP ERP Order Type to SAP EWM Item Type

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Interfaces → ERP Integration → Production → Map SAP ERP Order Type to SAP EWM Item Type |

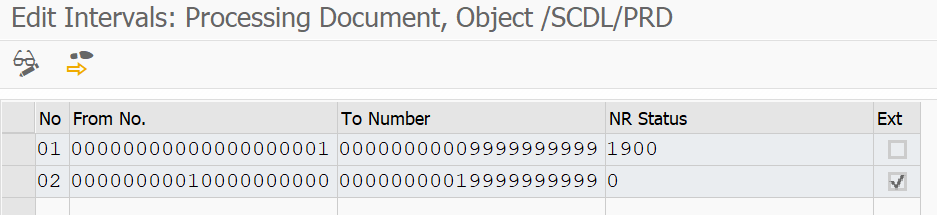

Define Number Range for Production Material Request

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Delivery – Warehouse Request → Number Ranges → Define Number Range for Production Material Request |

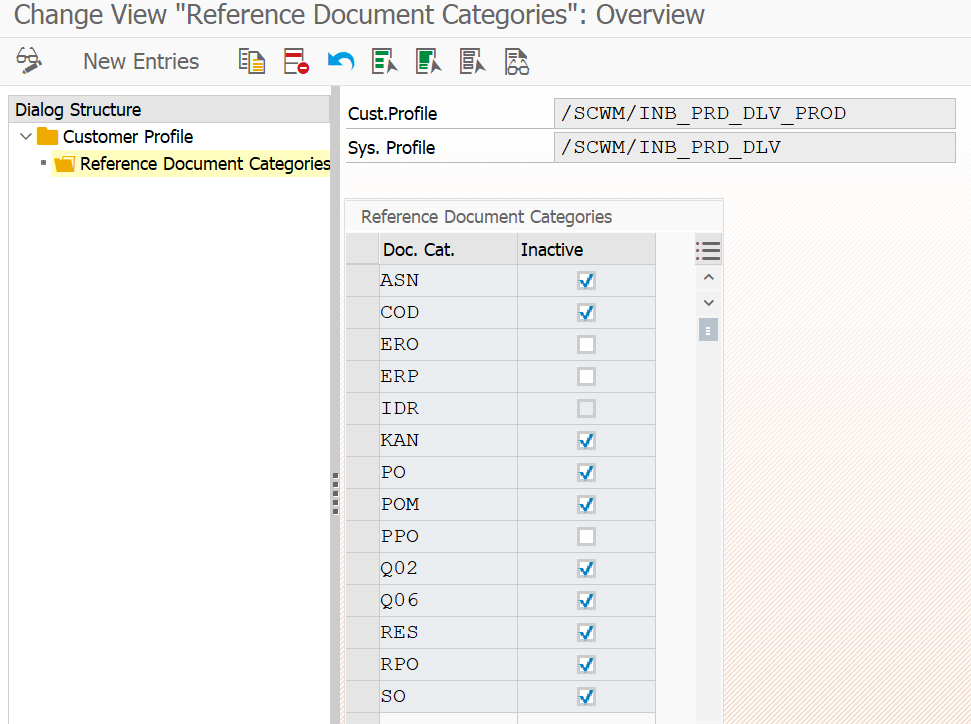

Define Reference Document Type Profiles

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Delivery – Warehouse Request → Reference Documents → Define Reference Document Type Profiles |

Settings for Warehouse Processes

Settings for Warehouse Order Creation

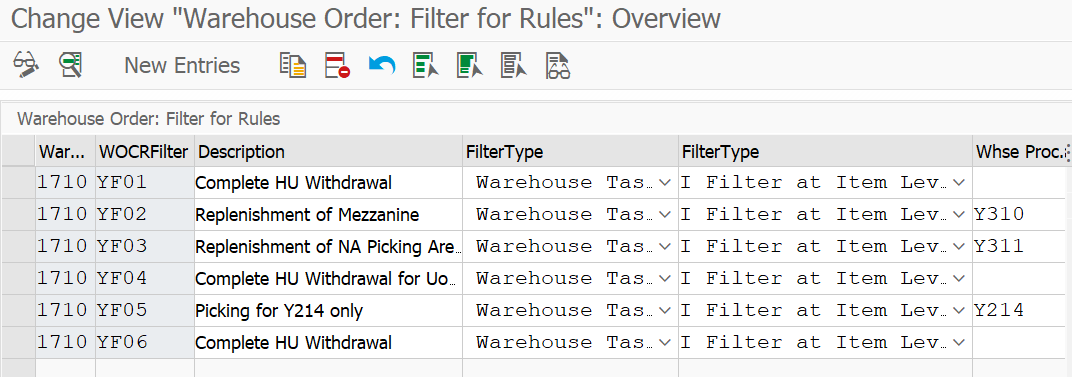

Define Filters for Warehouse Order Creation Rules

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Order → Define Filters for Warehouse Order Creation Rules |

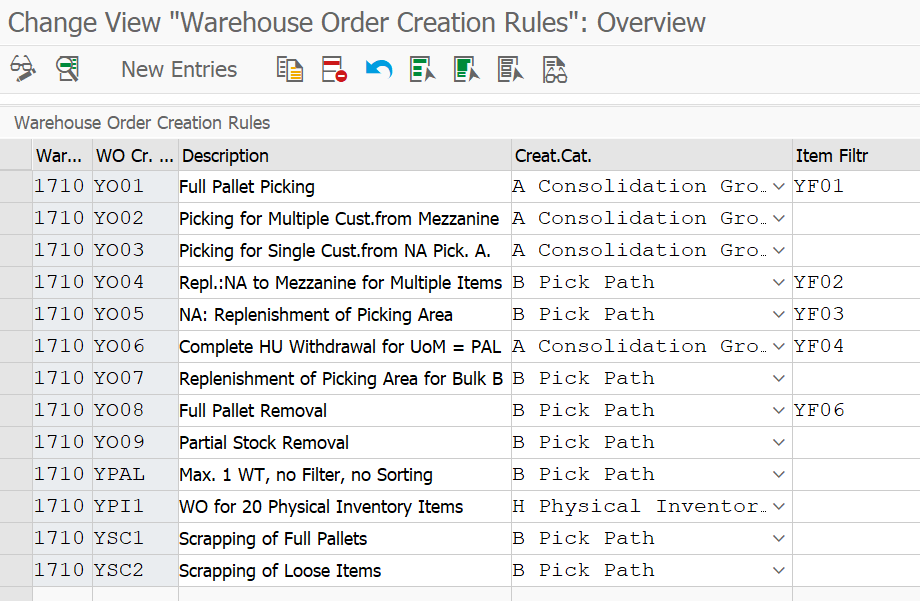

Define Creation Rule for Warehouse Orders

You define warehouse orders (WO) creation rules to group warehouse tasks (WT) into WOs, creating optimized work packages for the picker.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Order → Define Creation Rule For Warehouse Orders |

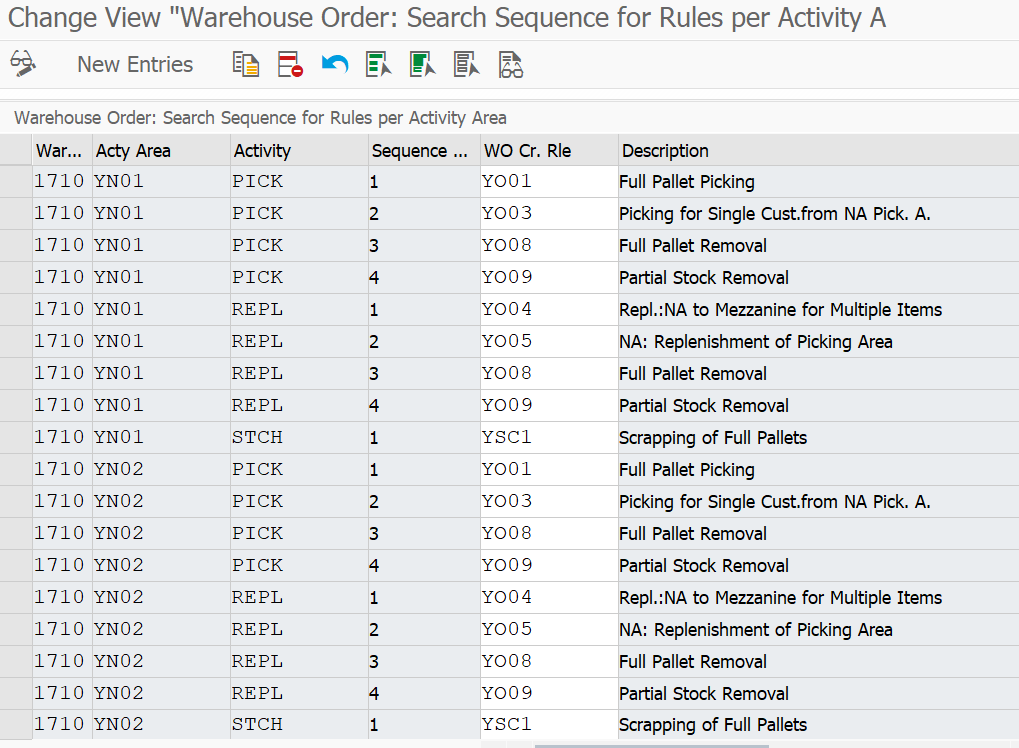

Define Search Sequence of Creation Rules for Activity Areas

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Order → Define Search Sequence of Creation Rules for Activity Areas |

Settings for Warehouse Task Creation

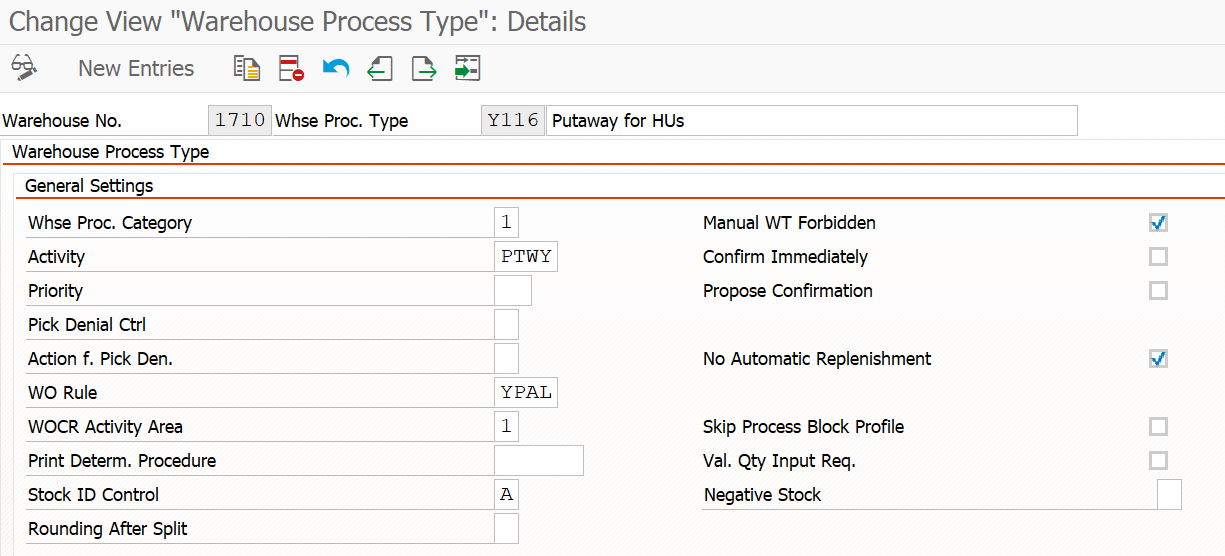

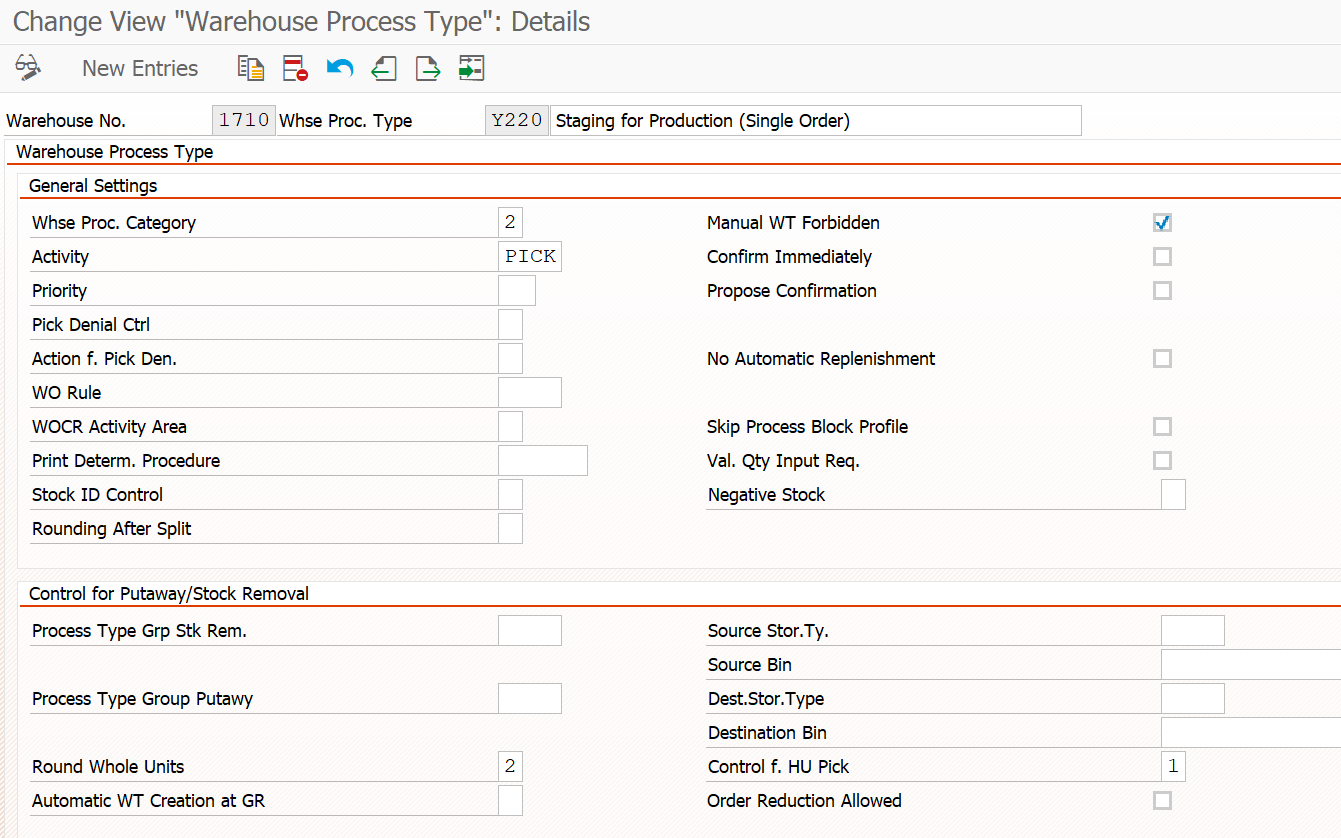

Define Warehouse Process Type

In this step, you create the process-specific warehouse process types (WPT).

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Warehouse Process Type |

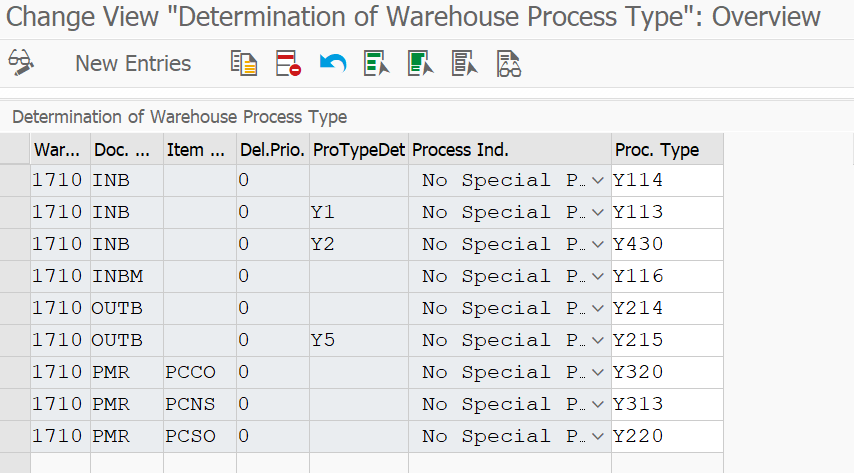

Determination of Warehouse Process Types

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Determine Warehouse Process Type |

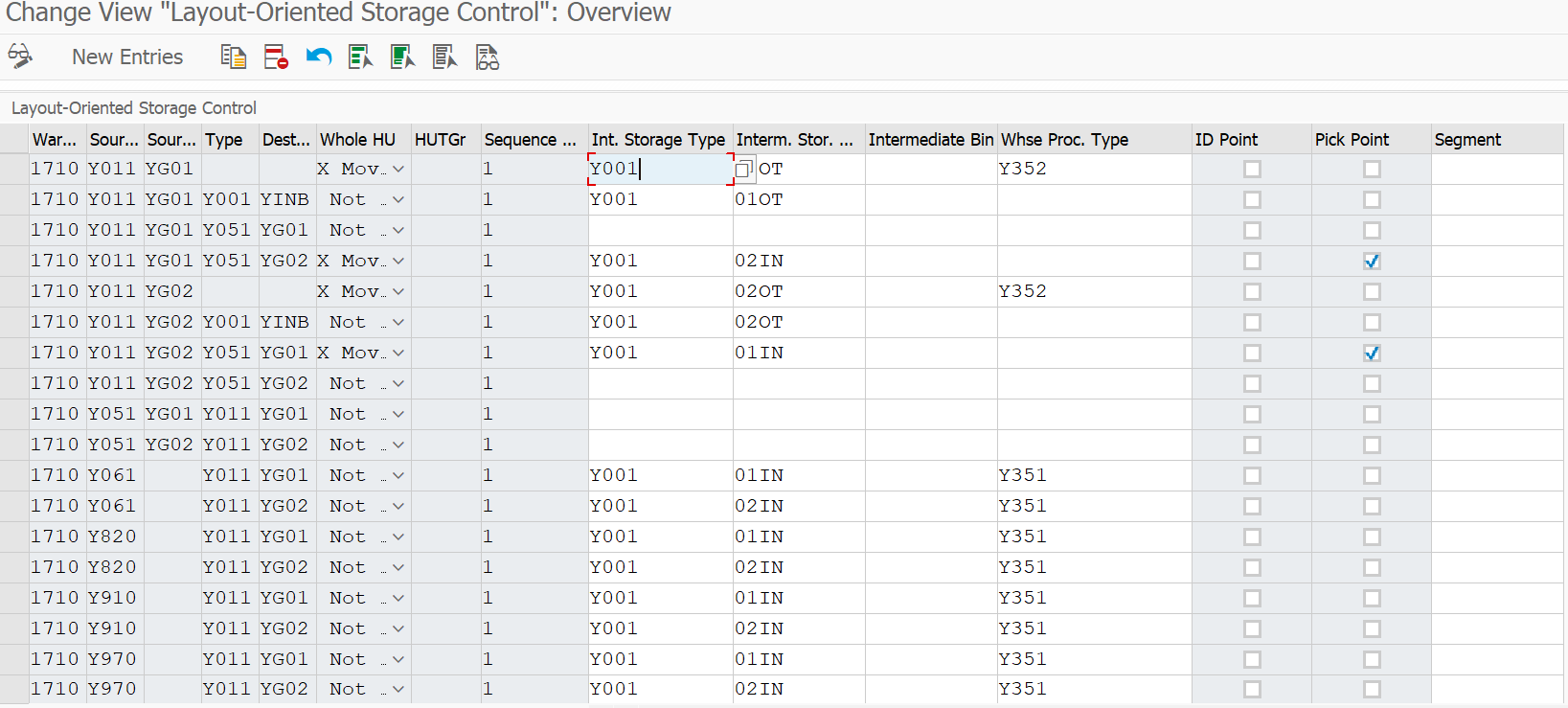

Advanced Settings for Warehouse Processes

Putaway Control

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Layout-Oriented Storage Process Control |

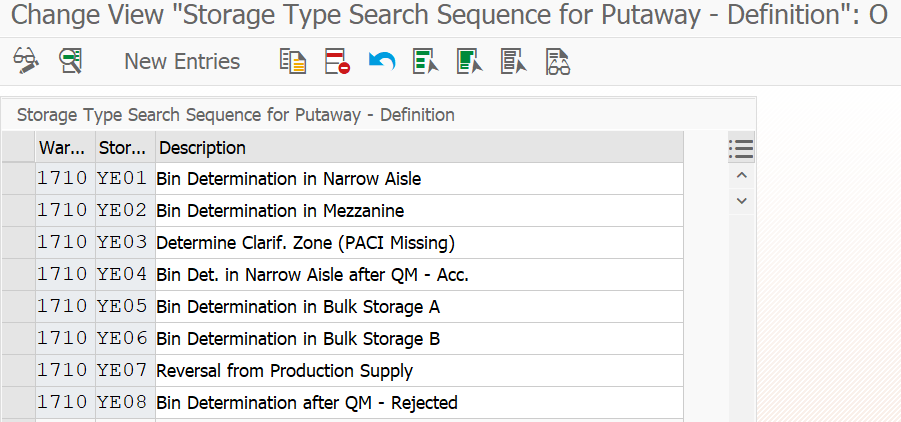

Define Storage Type Search Sequence for Putaway

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Storage Type Search → Define Storage Type Search Sequence for Putaway |

Assign Storage Types to Storage Type Search Sequence

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Storage Type Search → Assign Storage Types to Storage Type Search Sequence |

Specify Storage Type Search Sequence for Putaway

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Storage Type Search → Specify Storage Type Search Sequence for Putaway |

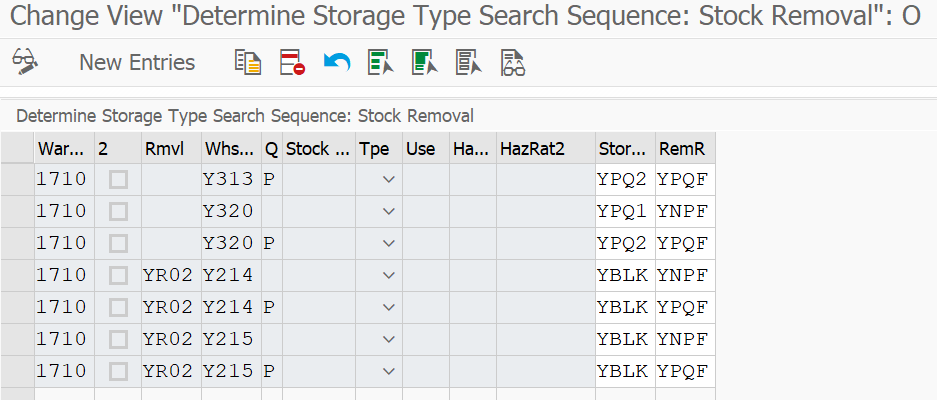

Stock Removal Control

Determine Storage Type Search Sequence for Stock Removal

Depending on several attributes such as warehouse process type, stock removal control indicator of the product or various stock attributes, the system determines the storage type search sequence.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Goods Issue Process → Strategies → Determine Storage Type Search Sequence for Stock Removal |

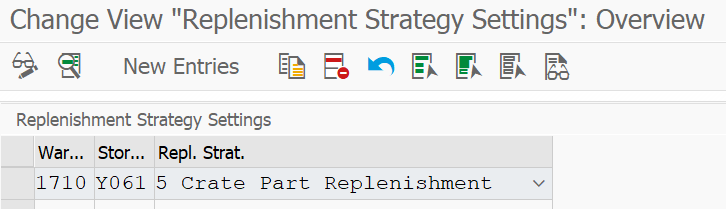

Replenishment

Activate Replenishment Strategies in Storage Types

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Internal Warehouse Processes → Replenishment Control → Activate Replenishment Strategies in Storage Types |

Configure Advanced Production Integration

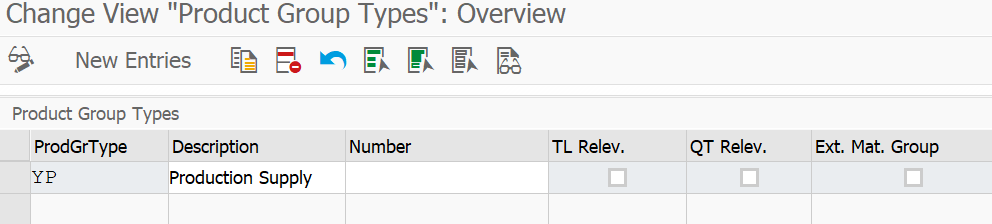

Define Product Group Types

In this IMG activity, you define product group types. You can then assign values to these under Define Product Groups.

Product group types and product groups serve to group products of the same kind. You define a product group type for the criterion with which the product groups are to be formed.

You can assign product group types to a product in the product master on the Properties 2 tab page.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → SCM Basis → Master Data → Product → Product Groups → Define Product Group Types |

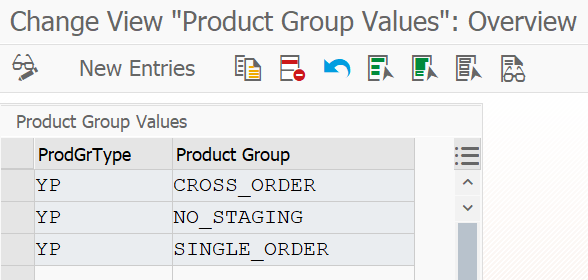

Define Product Group

In this IMG activity, you define the possible product groups for a product group type.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → SCM Basis → Master Data → Product → Product Groups → Define Product Groups |

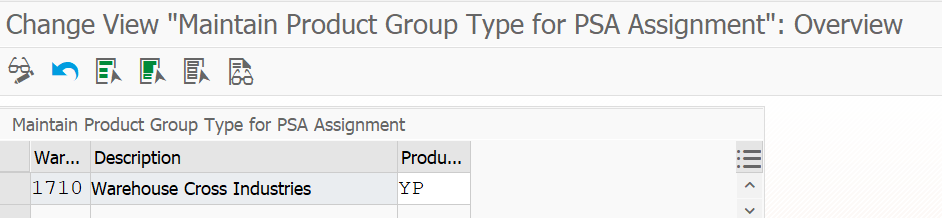

Maintain Product Group Type for PSA Assignment

This activity is required if the bin assignment to a production supply area (PSA) is not product-specific but product-group-specific. You need to define a product group type in Customizing before you make this assignment.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Production Supply → Maintain Product Group Type for PSA Assignment |

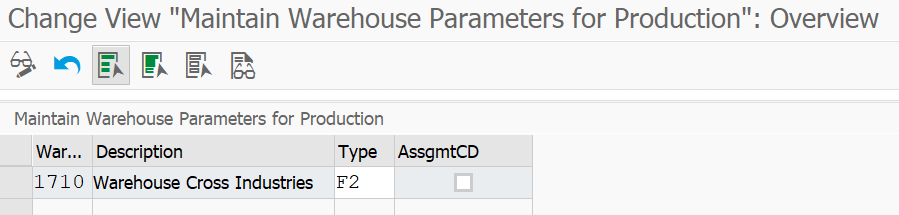

Maintain Warehouse Parameters for Production

In this Customizing activity, you can define and change the default stock type that the system uses for staging for production in each of your warehouses.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Production Supply → Maintain Warehouse Parameters for Production |

Resource Management

Define Queues

Warehouse Orders and Tasks to be processed within the RF / Mobile Data Entry UIs are assigned to specialized RF Queues. The Queue Naming follows a logic indicating the “Activity” as well as the source and destination activity area/storage type.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Resource Management → Define Queues |

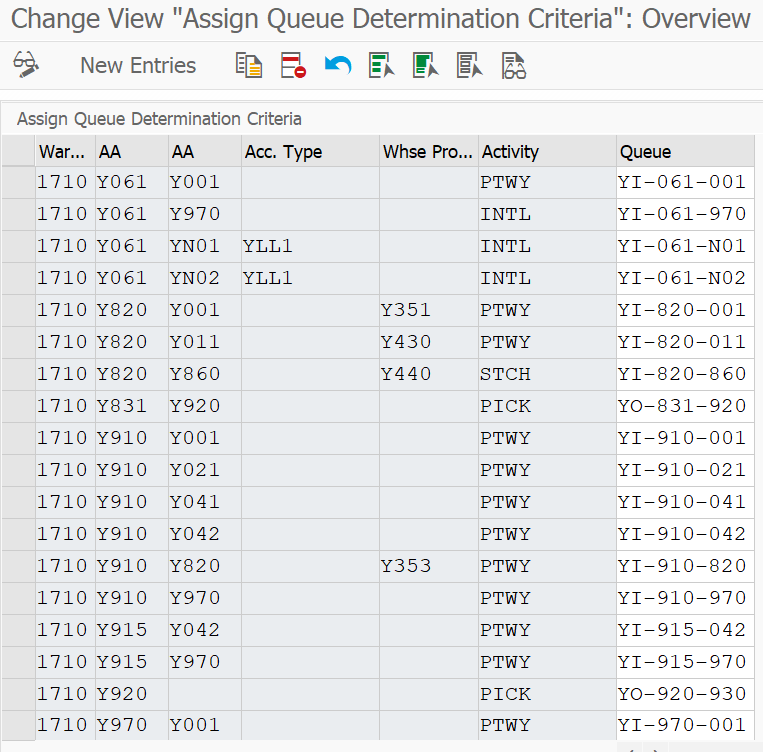

Define Queue Determination Criteria

You define queue determination criteria such as activity area, bin access type, and warehouse process type to assign warehouse orders to different queues.

| IMG Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Resource Management → Define Queues |

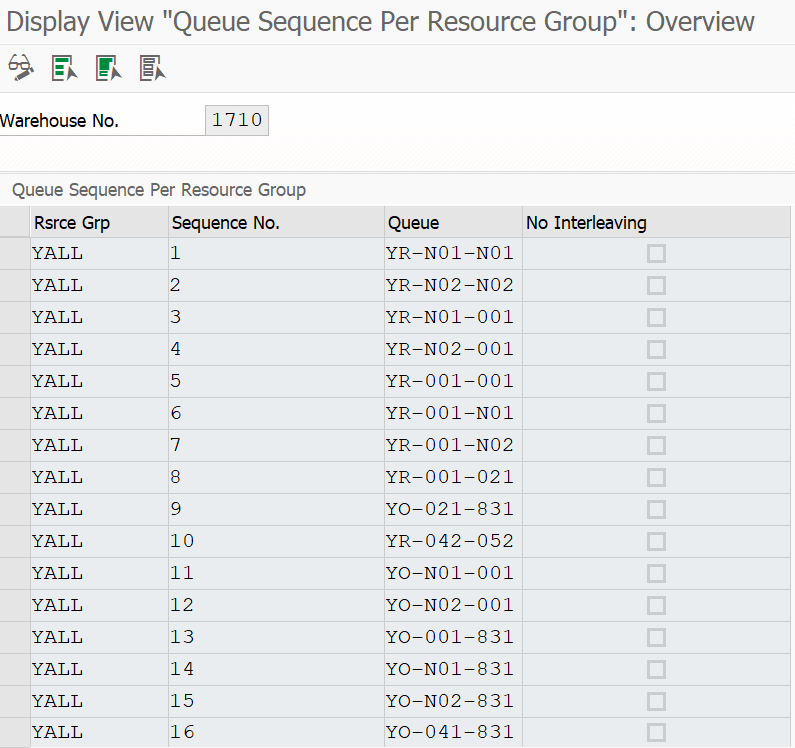

Maintain Queue Sequence for Resource Group

| Easy Access Menu

(SAP EWM) |

SCM Extended Warehouse Management – Extended Warehouse Management – Master Data – Resource Management – Maintain Queue Sequence For Resource Group |

| Transaction Code | /SCWM/QSEQ |

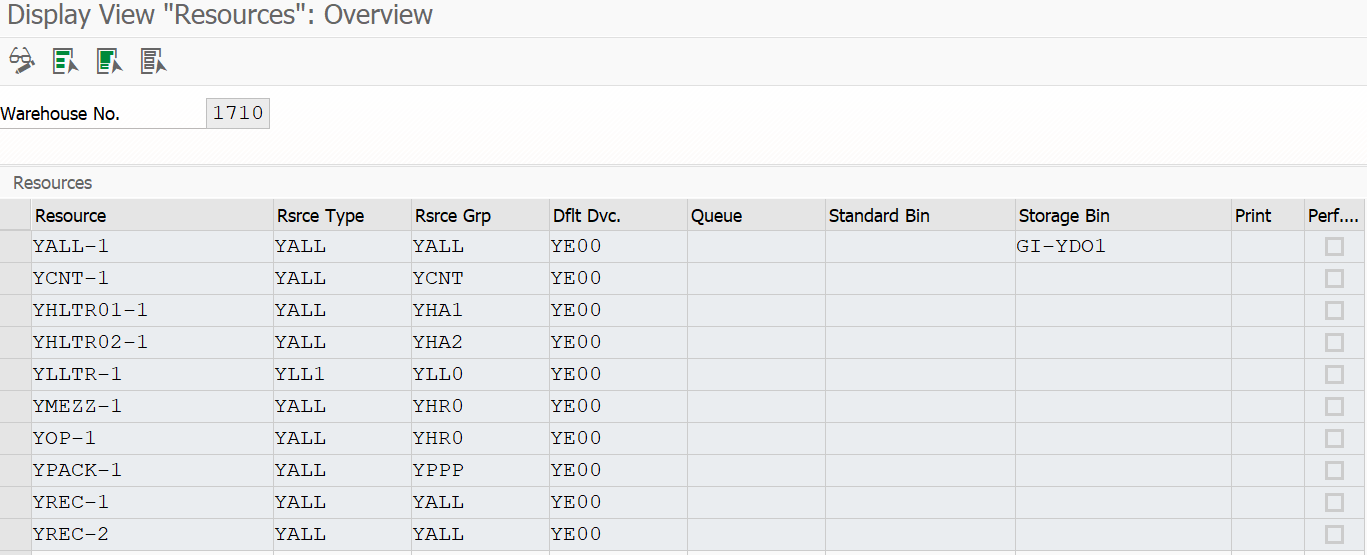

Maintain Resource

| Easy Access Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Resource Management → Maintain Resource |

| Transaction Code | /SCWM/RSRC |

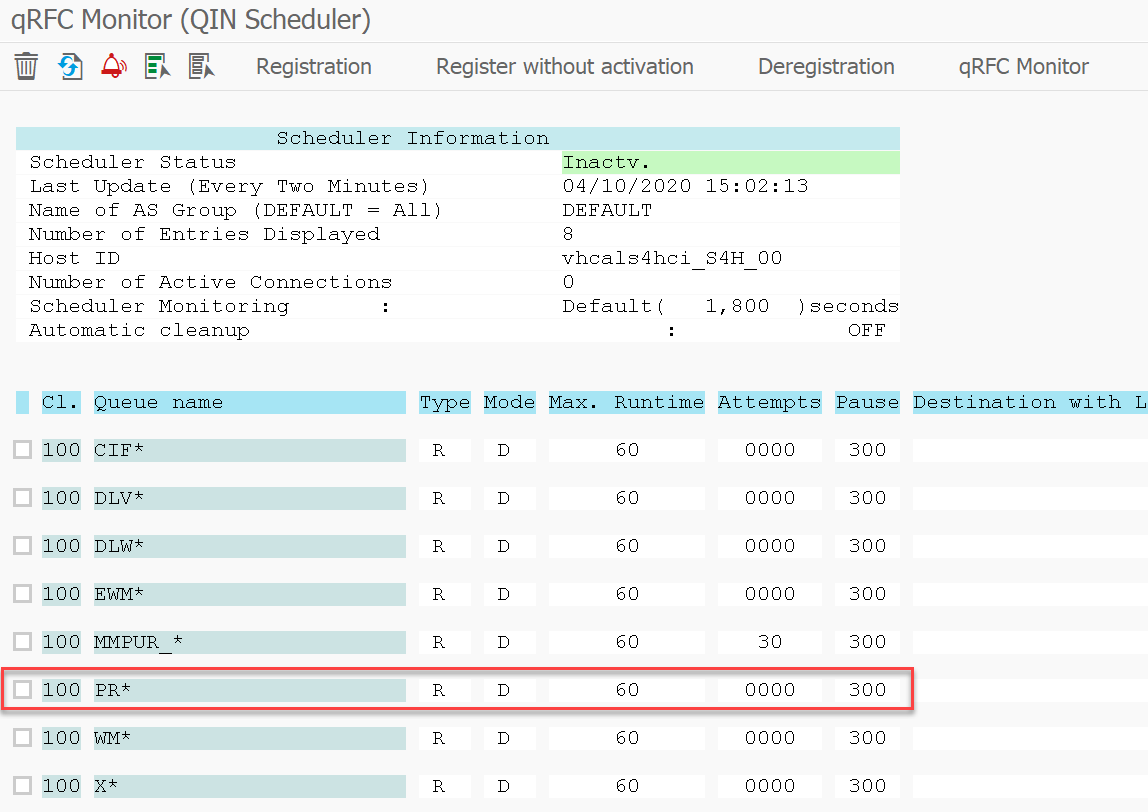

Maintain qRFC Monitor Settings (QIN Scheduler)

The scheduler for inbound queue in EWM is set up, which enables automatic processing of messages in inbound queue.

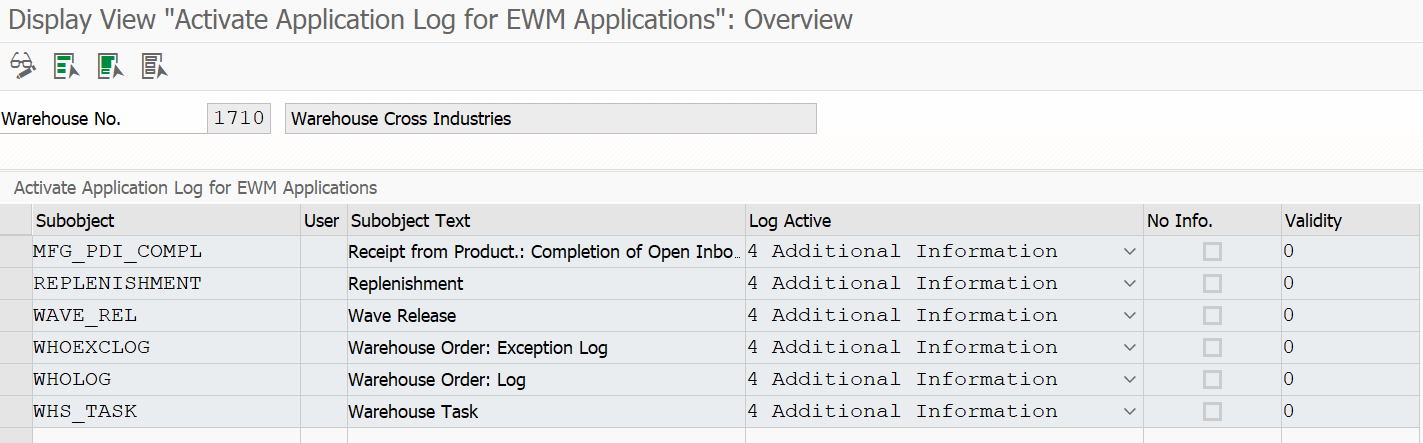

Activate Application Log in EWM

In order to be able to better analyze technical problems within the application, you can activate application logs which you later review in case of unexpected issues.

| Easy Access Menu

(SAP EWM) |

SCM Extended Warehouse Management → Extended Warehouse Management → Settings → Application Log → Activate Application Log |

| Transaction Code | /SCWM/ACTLOG |

BAdI for Single-Order Staging

After implementing the BAdi, system calculates the proposed quantity for single-order staging material with the following logic:

-

- Call the standard logic, look up the open required quantity.

-

- If the open required quantity is > 0, exactly the open required quantity is proposed for staging.

-

- If the open required quantity is <= 0 , the system will propose 0 as staging proposal.

-

- Access the activity using one of the following navigation options:

| SAP EWM IMG Menu | SCM Extended Warehouse Management ® Extended Warehouse Management ® Business Add-Ins (BAdIs) for Extended Warehouse Management® Goods Issue Process ® Production ® Staging ® BAdI: Data Collection for Staging for Production |

| Transaction Code | SPRO |

-

- Confirm the information Creating BAdI implementation for BAdI /SCWM/EX_MFG_STAGE_INFO of enhancement spot /SCWM/ES_MFG_STAGE

-

- On Create Enhancement Implementation dialog box, make the following entries:

| Field Name | Entry Value |

| Enhancement Implementation | YEWM_ES_MFG_STAGE |

| Short Text | Staging for Production |

-

- Choose

-

- Choose Local Object on the next screen.

-

- On the Enhancement Implementation : Create BAdi Implementati screen, make the following entries:

| Field Name | Entry Value |

| BAdI Implementation | YEWM_IM_MFG_STAGE_INFO |

| Implementing Class | YEWM_CL_IM_MFG_STAGE_INFO |

| BAdi Definition | /SCWM/EX_MFG_STAGE_INFO |

-

- Choose

-

- On the Create Implementation Class dialog box, select the class /SCWM/CL_EI_MFG_STAGE_INFO and choose button Inherit from Sample Class.

-

- Choose Local Object on the next scree.

-

- On the Enhancement Implementation YEWM_ES_MFG_STAGE change screen, under tab page Implementation Elements, double-click on the Implementing Class on the left-hand side navigation area.

-

- Choose Change Class button beside the implementation class YEWM_CL_IM_MFG_STAGE_INFO.

-

- On the Class Builder: Change Class YEWM_CL_IM_MFG_STAGE_INFO screen, under tab page Methods, put the cursor on method QUANTITY_PROPOSAL.

-

- Click the button

-

- On the Class Builder: Change Class YEWM_CL_IM_MFG_STAGE_INFO Change screen, remove all the source code, copy and paste the following example code :

METHOD quantity_proposal.

DATA: lv_quan_pro_opuom TYPE /scwm/de_quantity,

lv_quan_open_opuom TYPE /scwm/de_quantity.

FIELD-SYMBOLS: <ls_stage_item> TYPE ys_stage_item.

* standard quantity proposal

CALL METHOD super->quantity_proposal

EXPORTING

it_psa_packspec = it_psa_packspec

CHANGING

ct_stage_item = ct_stage_item.

LOOP AT ct_stage_item ASSIGNING <ls_stage_item>.

* single order staging: propose complete quantity of the PMR item

IF <ls_stage_item>-staging_method = /scwm/if_mfg_stage_consume_c=>sc_stage_method_single_order.

IF <ls_stage_item>-quana_open > 0 AND

<ls_stage_item>-altme_pro IS NOT INITIAL.

me->convert_quan(

EXPORTING

iv_matid = <ls_stage_item>-matid

iv_batchid = <ls_stage_item>-batchid

iv_unit_to = <ls_stage_item>-altme_pro

iv_quan_from = <ls_stage_item>-quana_open

iv_unit_from = <ls_stage_item>-altme

CHANGING

cv_quan_to = <ls_stage_item>-quana_pro ).

“<ls_stage_item>-quana_pro = ceil( <ls_stage_item>-quana_pro ).

ELSE.

<ls_stage_item>-quana_pro = 0.

ENDIF.

ENDIF.

ENDLOOP.

ENDMETHOD.

-

- Choose

-

- On the next screen, select all the objects for activations and choose

-

- On the Enhancement Implementation YEWM_EI_MFG_STAGE Change screen, under tab page Implementation Elements, double-click on the Filter Val. in the left-hand side navigation area.

-

- Choose Create Combination

-

- Double click on ???? in Value 1

-

- On the Change Filter Value dialog box, make the following entries :

| Field Name | Entry Value | Comment |

| Value 1 | <Warehouse Number> | Enter the Warehouse number, for example 1710 |

| Comparator 1 | = |

-

- Choose

-

- On the Enhancement Implementation YEWM_ES_MFG_STAGE Change screen, choose

Conclusion

Warehouse consultant able to configure the required settings to execute the advanced production integration within S/4HANA Embedded EWM.

Leave A Comment?

You must be logged in to post a comment.