MRP run or planning run is an engine which is used to fill the demand and supply gap. Issues and Receipts are called MRP Elements. Issues include PIRs, dependent requirements, order reservations, sales orders, issuing stock transfer orders, etc. Receipts include production orders, purchase requisitions, purchase orders, open production orders, receiving stock transfer order, schedule lines, etc.

MRP Parameters

MRP parameters are required to run material requirement planning to meet PIR, and to use routing information.

Processing Key

- NetChange − In this run system, consider those material which has undergone some changes from the previous MRP run.

- NetChange in Planning Horizon − This run considers the requirement in predefined planning horizon and not like net change, which checks the future requirements. In this run, the system considers only those material which has undergone some changes from their last MRP run.

- Regenerative Planning − In this run, the system considers all the materials irrespective of changes. It is time consuming and not common in Production planning.

Scheduling

- Basic Scheduling − It only calculates the basic dates for orders in MRP run and in-house production time for material master in use.

- Lead Time Scheduling − In this MRP, production dates are defined by lead time scheduling for planned orders.

Running MRP for All Products

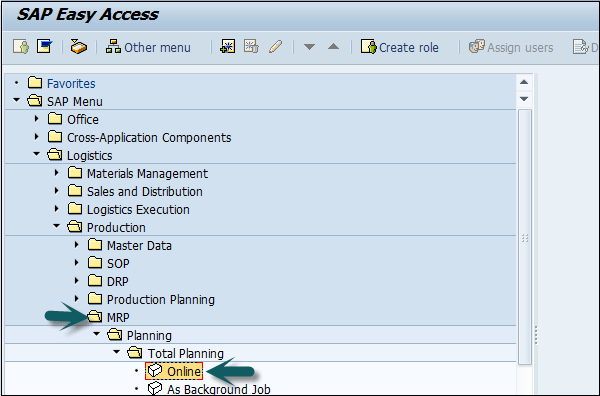

Use T-code: MD01 or go to Logistics → Production → MRP → Planning → Total Planning → Online

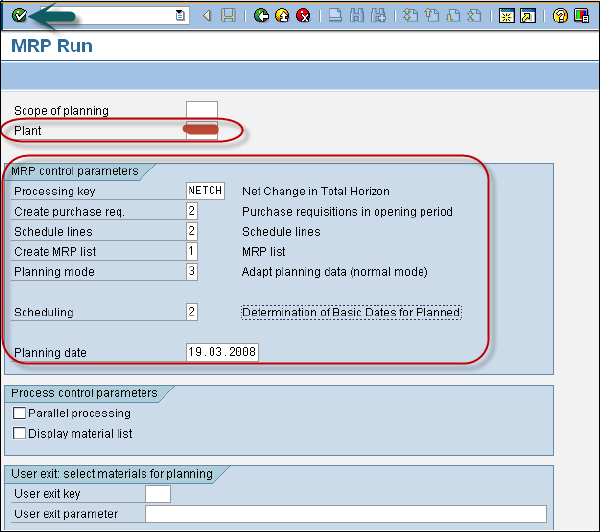

To run MRP with Net Change in planning horizon, enter the following details −

- The manufacturing Plant for which you want to calculate MRP run.

- The processing key as NETCH.

- Input 2 in Create Purchase req. shows purchase requisition in the opening period.

- Input 2 for schedule lines shows.

- Input 1 in MRP List and the system will create MRP list similar to stock/requirement list for later analysis of previous MRP run.

Planning mode 3 as we will delete and recreate all planning data for all materials.

Enter Scheduling indicator 2 shows MRP will do lead time scheduling and consider routing times to calculate planned order dates.

Click the tick mark on top of the screen.

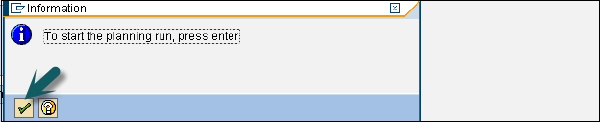

If you are sure on MRP run, click the tick mark.

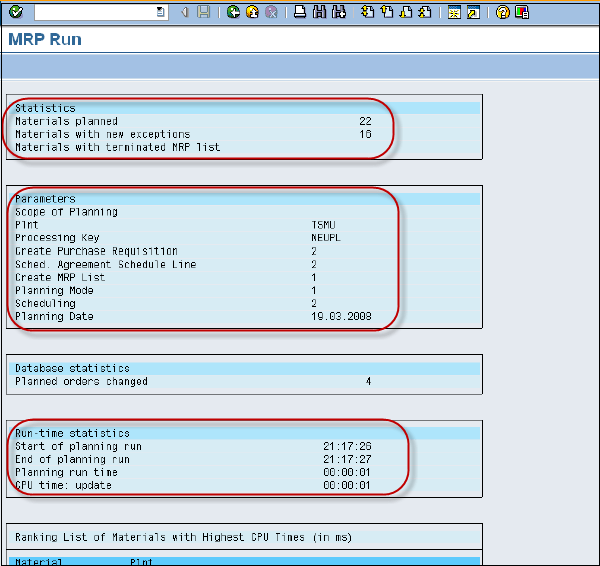

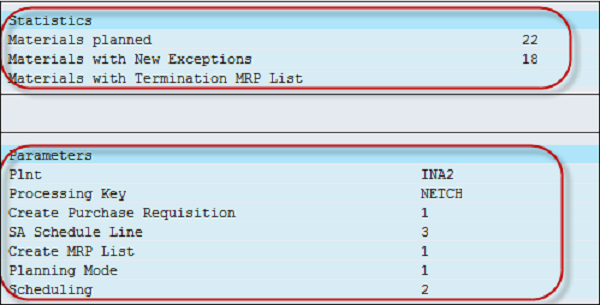

The system will take some time to run MRP and calculation is done. You can see the material requirement and what parameters have been considered during the run.

To perform MRP run for a single material, use T-Code: MD02 or go to Logistics → Production → MRP → Planning → Single item Multilevel

This is used to plan individual item planning. Enter the following details −

- Material number and Plant

- Processing key, NETCH (Net Change for total horizon)

- Create purchase req. 2

- Delivery schedules 2

- Create MRP list 1

- Planning mode 3

- Scheduling 2

Click the tick mark on top of the page.

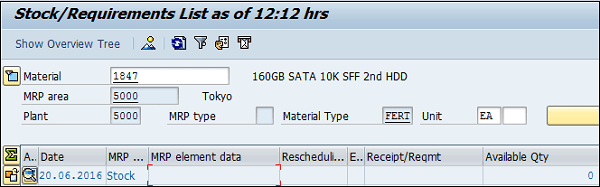

MRP Evaluation: Stock/Requirement List

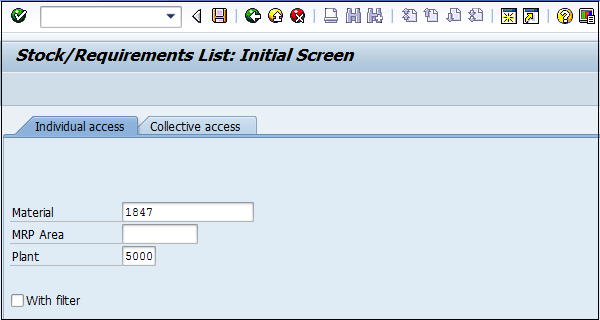

This is used to see current stock and planned receipts. Use T-code: MD04

Enter Material and Plant and click the tick mark on top of the page.

BOM for material was exploded. Enter Purchase requisition.

Leave A Comment?

You must be logged in to post a comment.